In today’s highly competitive automotive production and industrial industries, speed and precision are crucial to success. Modern workshops, be it automobile repair centers or large repair centers, are facing growing demands for speedy repairs with a minimum of errors and cost. This is the point at which Electronic Parts Catalogues (EPC) software is used.

EPC software can digitise old parts catalogues, turning them into searchable, interactive databases that help streamline processes. Why is this technology important? This article examines the definition of benefits, the advantages, how to implement, and the impact on the real world of EPC software, and focuses on its significance in the future-proofing of workshops.

What is Electronic Parts Catalogue Software?

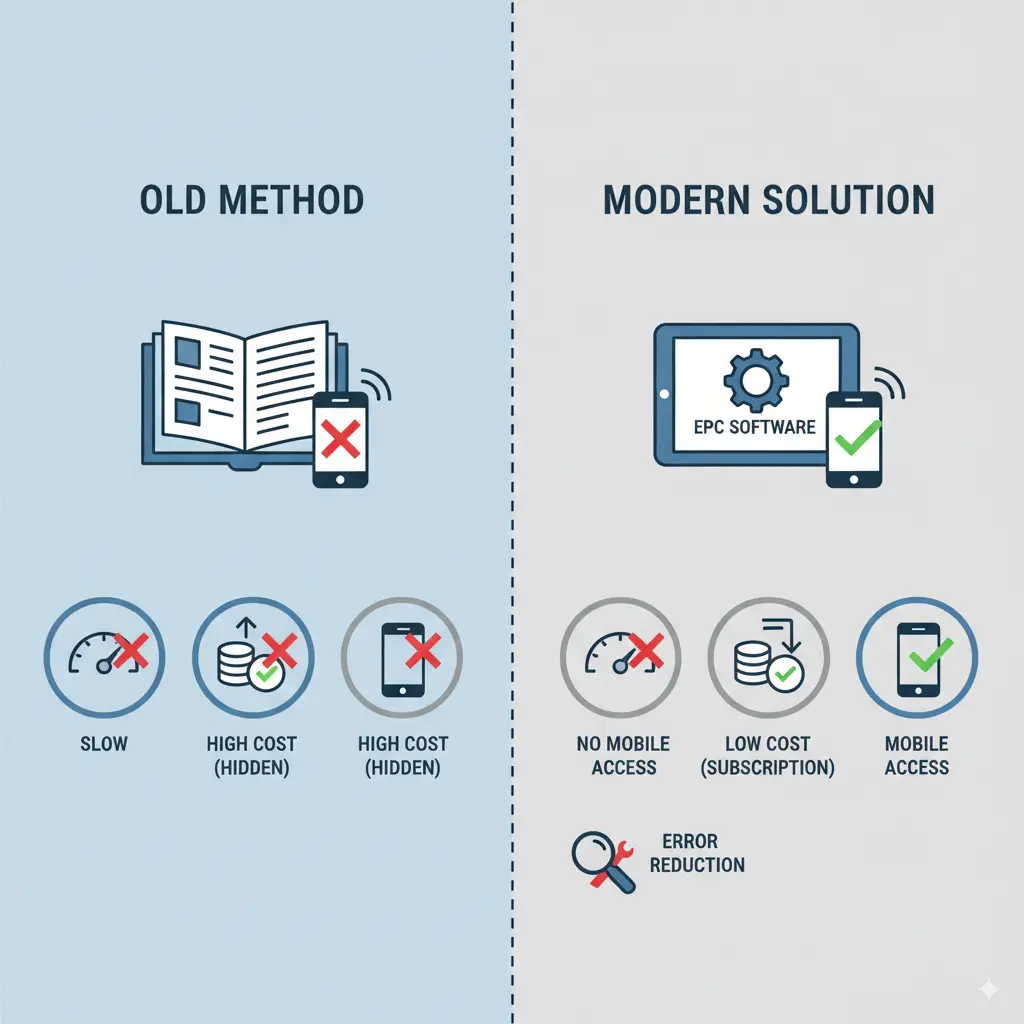

Electronic Parts Catalogues software, frequently abbreviated EPC, is a computer-based tool that acts as a complete database of spare and replacement components. Contrary to traditional paper catalogs, EPCs contain detailed information about components, such as part numbers, descriptions of the components, images, compatibility information, and prices. The user can search for components using keywords, Vehicle Identification Numbers (VINs), or interactive diagrams, making it easier to find the exact component required for repair.

EPC software is employed in auto repair shops, dealerships, manufacturing facilities, and aftermarket service providers. It is integrated with other systems, such as inventory management, order platforms, or shop-management software, to allow seamless workflows. For example, in the context of auto repair, technicians can connect to EPCs directly from mobile devices or workstations to confirm the specification of the part when performing the diagnostic process. Advanced features could include 3D visualizations, real-time inventory checks, and automated order processing, which improve usability over the static list.

The shift from printed paper catalogs to electronic EPCs has addressed the most pressing issues in modern workshops, including outdated information and manual searching inefficiencies. By centralizing information, EPC software ensures that workshops have access to the most recent updates from manufacturers, which reduces the chance of using outdated components.

Key Benefits of EPC Software for Modern Workshops

The use of EPC software isn’t a fashion–it’s an imperative prompted by competitive pressures and technological advances. These are the main reasons why it’s important:

1. Enhanced Efficiency and Productivity

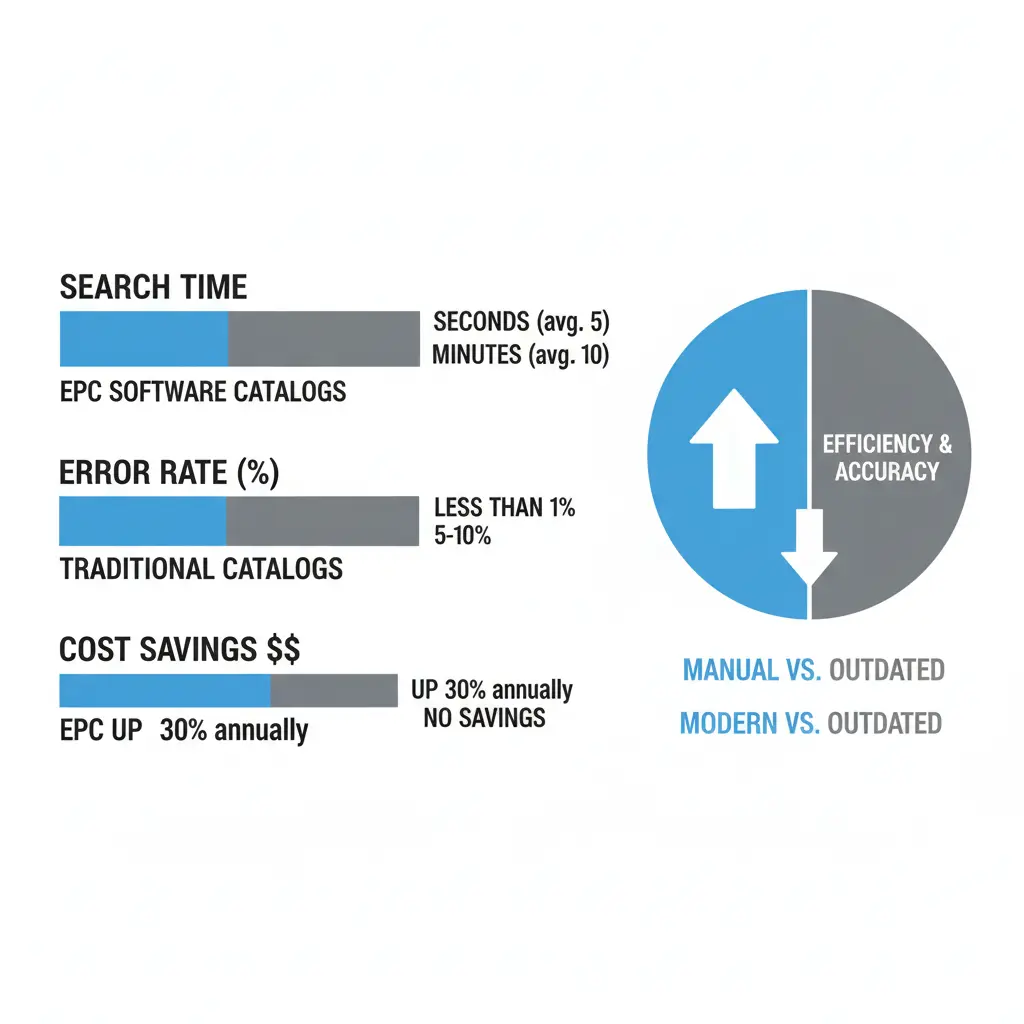

In busy workshops, a lot of time is spent. Traditional catalogs require you to flip through pages or reference several sources, which could delay repairs. EPC software can perform instant searches, usually with filters for the make, model, year, or type of part. Technicians can find parts quickly, view exploded drawings, and check compatibility, reducing the time of searching from minutes to just a few seconds.

This is a benefit for auto repair facilities, which means a quicker time to repair for clients. Integrating repair orders with software enables one-click ordering, automating the entire process from identification to purchase. Studies have shown that catalogs with digital images can decrease downtime for machines by streamlining repairs, which allows workshops to manage more work each day.

2. Improved Accuracy and Reduced Errors

Making the wrong purchase is a frequent and costly error in workshops. EPC software helps to avoid this by supplying accurate, current information directly from the manufacturer. Features such as VIN decoding make sure that parts are compatible with the exact vehicle model, and visual aids such as 3D models assist technicians in verifying parts without physically disassembling them.

Accuracy extends to managing inventory. Real-time updates on the availability of parts will prevent stockouts or over-ordering and help optimize the level of stock. In manufacturing workshops, it reduces the need for rework and returns, thereby saving both time and resources.

3. Cost Savings and Operational Optimization

In reducing the number of errors and downtime, EPC software directly impacts the bottom line. Workshops can reduce unnecessary part purchases, lower labor costs through faster diagnosis, and improve inventory efficiency. Automated change management ensures that catalogs reflect current pricing and supersessions (replacements for discontinued parts), preventing financial loss due to outdated information.

For shops with multiple locations, cloud-based EPCs provide central access to the internet, eliminating the need to maintain physical catalogs at each location. The scalability of the system leads to greater cost savings, with some systems claiming to have reduced support requests by as much as 30% with self-service capabilities.

4. Real-Time Updates and Integration Capabilities

Modern workshops operate in highly dynamic environments, where specifications for parts change regularly. EPC software can connect to manufacturers’ databases for automated updates, making sure that users have the latest information about recalls, releases, and price changes.

Integrating with additional tools, for instance, Auto Repair Shop Management Software, can improve workflows. For example, linking EPCs to billing systems can automate invoices, while connecting to e-commerce platforms allows for direct purchase from suppliers. Interoperability is vital for workshops that utilize electronic vehicle inspections and mobile mechanic applications.

5. Better Customer Service and Satisfaction

Rapid, precise repairs help build confidence with customers. EPC software enables technicians to present clear estimates, displaying precise costs and parts in advance. In dealerships, it facilitates upselling by highlighting components or upgrading.

Mobile accessibility enables field technicians to access catalogs on-site, reducing waiting times for mobile repairs. This results in more customer retention and favorable reviews, which are essential for workshops operating in highly competitive markets.

6. Compliance and Future-Proofing

With the increasing requirements for emissions and vehicle safety, EPC software helps ensure compliance by flagging components for recalls or conforming to standards. As industries shift towards electric vehicles and smart cars, EPCs can incorporate data about new technologies, such as sensors or batteries for electric cars.

Cloud-based solutions can help ensure the future of operations with flexibility and scalability, making workshops ready for new technologies like AI-driven diagnostics.

How EPC Software Works in Practice

Implementing EPC software typically involves selecting the appropriate provider (e.g., Snap-on, PTC, or IntelliNet), followed by importing data from manufacturers and training employees. The software can be used on tablets, computers, or through web-based apps that have user-friendly interfaces with interactive graphics, search bars, and shopping cart integration.

In a typical process:

- A technician enters a VIN or scans the barcode.

- The system displays pertinent diagrams and lists of parts.

- Parts are picked and ordered immediately, with inventory checks.

- Integration seamlessly integrates with the shop system’s ERP or CRM to provide seamless monitoring.

Case studies from companies demonstrate ROI in a matter of months, with auto shops reporting 20-40% faster part search results and reduced errors.

Challenges and Considerations

Although essential, the adoption of EPC software is a major investment in integration and training. Workshops should assess the providers based on user-friendliness, compatibility, and support. Data security is another factor to consider, especially when it comes to cloud-based systems that handle sensitive information from vehicles.

Conclusion

Electronic Parts Catalogues software is no longer a luxury, but the foundation of modern workshops that want to remain in the game. It improves efficiency in accuracy, precision, and customer satisfaction, while reducing cost. EPCs transform how repairs are managed. As technology advances, investing in reliable EPC options will ensure that your repair shop is successful in the digital world. If you’re a repair shop, think about the EPC options now to gain these advantages.

FAQs

What exactly is Electronic Parts Catalogue (EPC) software?

EPC software acts as a database in digital format, which catalogs spare parts using specific information, search tools, and illustrations to help you identify and locate components quickly.

What are the reasons why modern workshops require EPC software?

It increases efficiency, minimizes mistakes, reduces costs, and offers real-time updates, making it necessary for quick and precise repairs in the competitive environment.

What is the difference between the EPC program and paper catalogs?

In contrast to static paper versions, EPCs can be searched, interactive, and up-to-date in real time with features such as 3D views and the ability to integrate features that paper cannot provide.

Does EPC software work with other tools for the workshop?

It often integrates with the management of inventory, billing, or repair software to ensure efficient processes.

What are the charges for EPC software?

Costs can vary based on the provider and feature, usually with subscription fees. But, ROI is derived from the time savings and fewer errors. Evaluate the ROI depending on the size of your workshop.

Is EPC software appropriate for small workshops?

Absolutely; there are scalable solutions for small businesses, providing access to mobile phones and other basic features without excessive complexity.

How do I select the most appropriate EPC program for the workshop I am running?

Look for user-friendly interfaces, integration capabilities, live updates, and reliable customer service—review and test demonstrations from companies such as PTC or Snap-on.

What industries are most benefited by EPC software?

Primarily, automotive repair manufacturing, high-tech equipment, and dealerships; however, it can be adapted to any industry that requires complex machinery components.