In the constantly changing world of manufacturing, automotive repair, and equipment maintenance, managing part information is vital to operating success. Electronic Parts Catalogue (EPC) software is an alternative to static or paper-based PDF catalogues that offer greater functionality and accessibility.

This article provides a comprehensive analysis of the differences between EPC programs and conventional catalogues for parts, explaining their definitions, key differences, benefits, and real-world applications. No matter if you’re a workshop proprietor, technician, owner, or seller, understanding the differences will allow you to decide the best system for your requirements.

Key Takeaways:

EPC software is a powerful upgrade over traditional catalogues, offering real-time search, VIN decoding, and 3D diagrams that improve speed and accuracy. It reduces costs, integrates with ERP and inventory systems, and delivers a better user experience through mobile access and automation. While traditional catalogues may still serve as backups in low-tech settings, the future clearly leans toward EPC solutions, especially for industries like automotive, aerospace, and heavy equipment, where precision and efficiency are critical.

What is EPC Software?

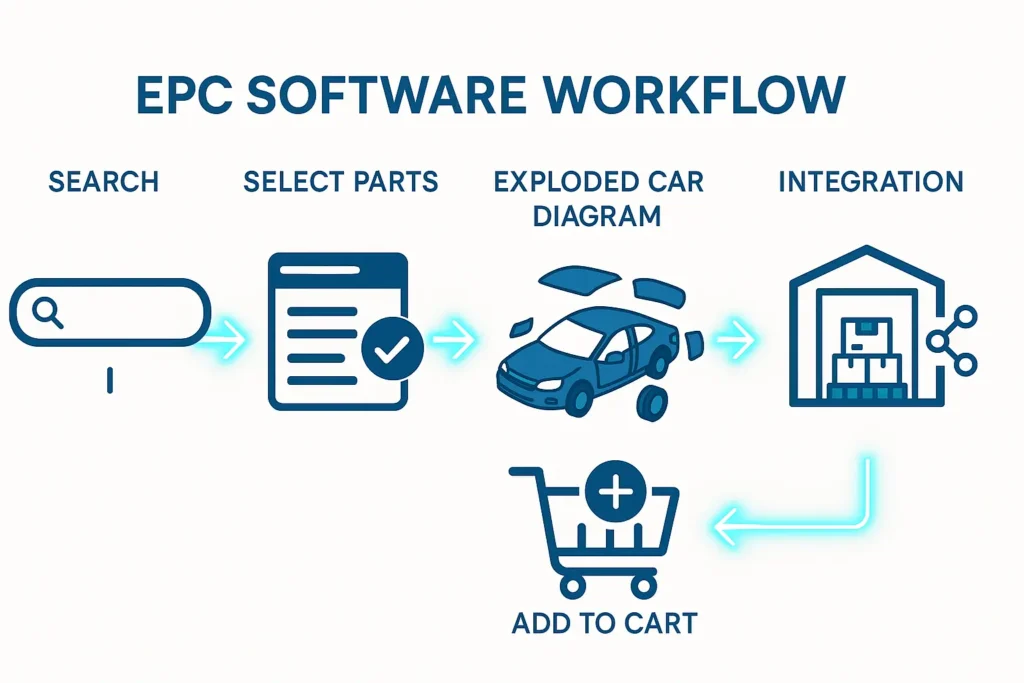

Electronic Parts Catalog software is an online platform that acts as a complete database of spare and replacement components. It enables users to search, locate components, and place orders through interactive interfaces, which typically include searchable databases, 3D graphics featuring exploded diagrams, and real-time supplier information. EPC systems are widely employed in sectors such as aerospace, automotive, and heavy machinery, and are integrated with the inventory management system, eCommerce, and ERP systems to create seamless workflows.

In contrast to static resources, EPC software is cloud-based or locally installed, offering mobile accessibility and automated features such as VIN decoding, which enables exact part matching.

What are Traditional Parts Catalogues?

Traditional parts catalogues are available in various formats, including non-interactive digital formats, physical media such as microfiches and printed books, and PDF files. They list the parts in descriptions of numbers, descriptions, and occasionally illustrations. They also require the manual use of pages or indexes. They have historically been the standard for dealerships and workshops.

They are often supplied by manufacturers in bound volumes or PDFs that are available for download. While they are useful for reference purposes, they do not contain dynamic elements and need to be updated regularly so that they reflect any changes to availability or specifications.

Key Differences Between EPC Software vs Traditional Parts Catalogues

The switch from traditional electronic systems represents an evolution from analog efficiency to digital. Below is a comparison side-by-side in table format to provide clarity:

| Aspect | EPC Software | Traditional Parts Catalogues |

|---|---|---|

| Format | Digital, interactive (software/app-based) | Physical (paper) or static digital (PDF) |

| Searchability | Advanced search with keywords, filters, VIN | Manual index or table of contents |

| Updates | Real-time or automatic from manufacturers | Periodic reprints or manual downloads |

| Visual Aids | 3D models, exploded views, zoomable images | Static illustrations or diagrams |

| Integration | Links with inventory, ordering, and CRM systems | Standalone, no automation |

| Accessibility | Mobile, cloud-based, multi-user | Location-bound, single-user |

| Cost Structure | Subscription or one-time fee with updates | Initial printing/distribution costs |

| Error Reduction | High (automated compatibility checks) | Prone to human error in lookups |

This table shows the ways EPC software overcomes the limitations of traditional methods which makes it more able to adapt to changing needs.

Advantages of EPC Software Over Traditional Parts Catalogues

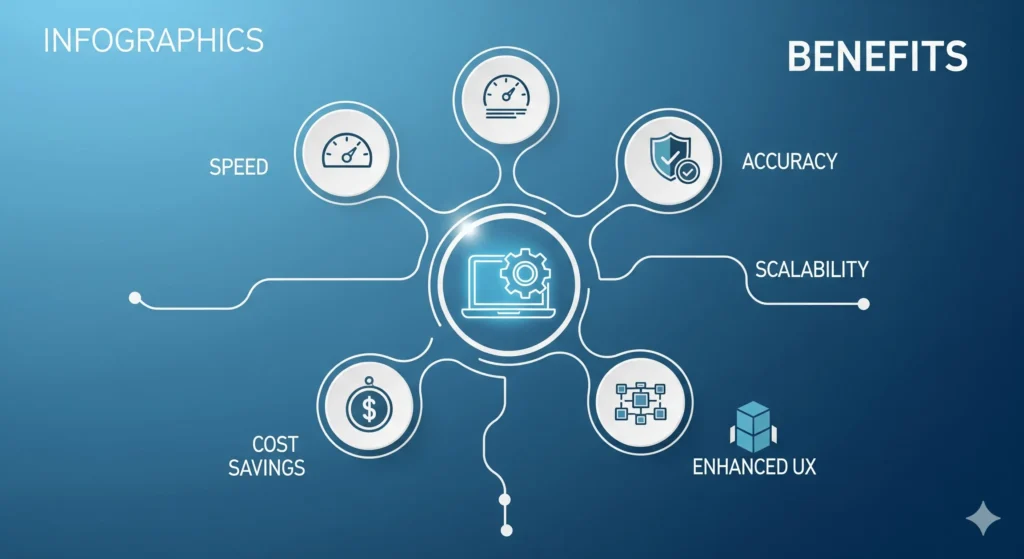

EPC software has numerous advantages that make it ideal for modern operations:

1. Speed and Efficiency

With the capability to search in real-time, technicians can find parts in a matter of seconds, rather than hours scrolling through pages. Interactive features such as hyperlinks and filters speed up the process and reduce the time spent in workshops.

2. Accuracy and Reduced Errors

EPC systems reduce the chance of errors by providing current data and tools for cross-referencing. For instance, they could detect obsolete parts or incompatibilities that traditional catalogues usually fail to notice until a fresh edition is published.

3. Cost Savings

While initial setup may be more expensive, EPCs cut long-term expenses by reducing costs for printing, minimizing the risk of incorrect orders, and optimizing inventory using real-time information. Businesses can report a 30% speedup in processing orders.

4. Scalability and Integration

EPC software adapts to the growth of business, allowing for many users and interfacing with other electronic tools. This is a great solution for international operations, where traditional catalogues require physical copies to be shipped.

5. Enhanced User Experience

Features such as 3D visualizations and mobile applications make EPCs user-friendly, which improves the training of new staff members and self-service portals for customers.

Disadvantages of EPC Software and When Traditional Catalogues Might Be Preferable

Although it has its merits, EPC isn’t without drawbacks:

1. Initial investment and learning Curve: Getting into EPC requires the purchase of software, training, and possibly IT infrastructure. This can be overwhelming for small-scale businesses.

2. Dependency on technology: Internet outages, power issues, or software glitches could cause access to be stopped, unlike physical catalogs which are always accessible.

3. Data Security: Data Security Risks. The digital systems could be vulnerable to cyberattacks, which require strict security measures.

Traditional catalogs are a great resource in low-tech settings like remote locations that have no reliable internet, or for those who prefer to use tactile references. They also do not have fees for subscriptions and serve as backups in the event of a digital failure.

Moving from the Traditional System to EPC Implementation Tips

Making the switch to EPC requires evaluating the providers such as IntelliNet, Documoto, or Components Engine, based on the features, compatibility, and support. Start by implementing a pilot program to train staff and move existing data. Many have reported quick ROI due to efficiency improvements.

Real-World Examples and Case Studies

In the automotive industry dealerships that use EPC have cut down on part ordering mistakes by 40 percent, which leads to better satisfaction of customers. Manufacturing companies like those that manufacture heavy equipment have embraced 3D EPCs to speed up troubleshooting which has reduced service time significantly.

Conclusion

EPC software surpasses traditional parts catalogs in a majority of modern situations because it offers speed as well as accuracy and integration with trends in digital transformation.

While traditional methods are still useful for niche applications but the future is geared towards EPC for its competitive edge with regards to efficiency as well as cost reductions. If you’re thinking about upgrading take a look at your workshop’s requirements and consider EPC alternatives to stay ahead of the curve in an industry that is dominated by technology.

FAQs

1. What is the primary distinction that exists between EPC software and the traditional parts catalogs?

EPC is interactive and digital that updates in real-time, whereas traditional catalogs are static paper or PDF formats, which require manual search.

2. What makes EPC software more suitable for modern workshops?

It improves efficiency, decreases mistakes, and is integrated to other software systems thereby saving both time and money over traditional methods that are no longer effective.

3. Are there any disadvantages in moving onto EPC software?

Yes, this includes the cost of starting up and a learning curve and reliance on technology but the benefits can outweigh the disadvantages in the case of growing companies.

4. How can small businesses gain by EPC software?

Absolutely, It is scalable. EPC solutions can provide low-cost services and access to mobile devices, making them feasible even for smaller-scale operations.

5. How are updates implemented in EPC software, compared to traditional catalogues?

EPC is updated automatically using cloud connectivity, whereas traditional printing requires fresh prints or downloads which may be frequent and expensive.

6. Which industries utilize EPC program the most?

Aerospace, manufacturing, automotive and heavy equipment industries in which precise identification of the part is crucial.

7. Are EPC software more secure than traditional catalogs?

EPC requires cybersecurity measures however, reputable providers provide encryption. Catalogues that are traditional have no cybersecurity risks, but they may be destroyed or lost physically.

8. What do I decide between EPC and conventional catalogs?

Assess your readiness for technology budget, as well as operational scale. If the efficiency and scale are important choose EPC but for simplicity, go with the traditional.