In the digital age, accuracy, speed and efficiency are crucial for businesses that work with complex products and parts. The Electronic Parts Catalogue (EPC) is revolutionising how manufacturers, service centres and dealers can manage, find and purchase parts.

No matter if it’s in or out of the automobile, agricultural, or machinery field, EPC systems are now vital to ensure smooth operations and to ensure that customers get the correct components quickly.

In this post, we’ll go deeper into the capabilities of Electronic Parts Catalogue (EPC) and benefits, applications and the future of EPCs and help you understand how they can be a game changer for contemporary enterprises.

What is an Electronic Parts Catalogue (EPC)?

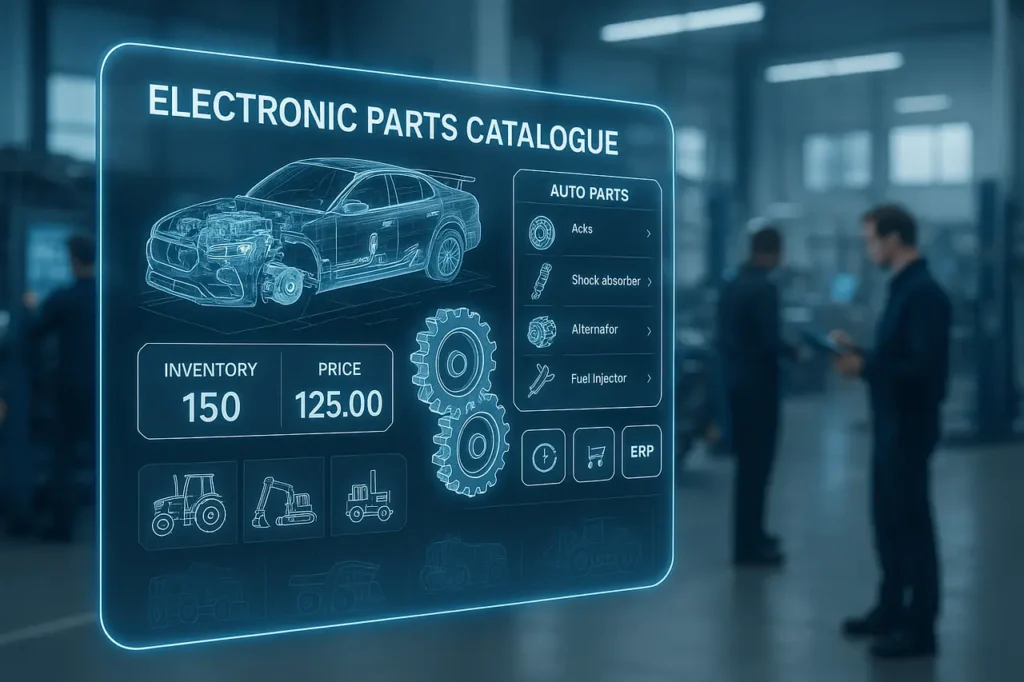

An Electronic Parts Catalogue (EPC) is a digital platform that can replace traditional printed catalogues or static PDFs. It allows distributors, manufacturers and even service centre owners to manage, store and exchange detailed information about the part dynamically.

Contrary to printed catalogues that are quickly outdated, EPCs provide real-time information about assemblies, parts and availability. Often, they are connected directly to ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), or E-commerce systems.

Simply stated, the EPC represents the central digital hub that allows users to look up parts, browse diagrams of assembly, monitor the status of their inventory, and even order from a single interface.

Core components of an EPC System

A typical EPC contains multiple modules to simplify operations across departments. Below are the essential components:

1. The Product and Part Details are detailed

The information for each component — which includes descriptions, specifications, compatibility and even supplier information. This eliminates the guesswork and guarantees that only the correct parts are ordered.

2. Assembly Drawings and Diagrams with Exploded

Users have access to visualisation diagrams that illustrate how various parts are interconnected within a system or machine. The “exploded view” is handy to technicians in the course of maintenance or repairs.

3. Real-Time Inventory Tracking

Modern EPCs are connected to the company’s warehouse system or ERP system, providing users with immediate updates on stock levels. This prevents over-orders or delays due to the non-availability of parts.

4. Prices and Options for Orders

Dealers and service centres can access price changes, discounts, prices and even place orders directly via the EPC interface. This eliminates the requirement to use paper or manual communication.

5. Integration with Business Systems

The most modern EPCs effortlessly integrate into:

- ERP systems are used for accounting and supply chain synchronisation

- CRM tools – for better customer data management

- eCommerce platforms allow customers to buy online directly

These integrations transform the EPC into the whole digital ecosystem and streamline procedures from parts lookup to fulfilment of sales.

How EPC Systems Work?

An EPC acts as an intermediary between data about products and those who require it. Here’s a simple workflow:

- Data input: Companies upload their detailed information on their products and parts to EPC. EPC system.

- Structure and Visualisation: It organises this information through visualisation diagrams, hierarchical logical structures and metadata.

- Access for users: Techs, dealers and customers have access to the EPC via a secure website.

- Search and Identify: Users search with parts numbers, keywords, or diagrams of visuals to identify the right component.

- Order and Sync: After selecting the option and enabling it, EPC will connect to your ERP or an e-commerce system to process your order and update the stock levels promptly.

This reduces human error, speeds up order processing and guarantees consistency of information throughout all platforms.

Industries that Benefit from EPC Systems

While EPCs were initially a part of the automobile industry, they’ve since extended into a variety of areas:

1. Automotive

Dealers and manufacturers of cars are heavily dependent on EPCs to find the right parts across different model variations. They help mechanics locate parts quickly, thus reducing downtime.

2. Agricultural Equipment

A farm machine usually includes many components—EPCs aid dealerships and repair centres in finding the correct parts quickly in the maintenance or harvest seasons.

3. Industrial and Heavy Equipment

From the beginning of construction to production, EPCs ensure engineers can get real-time information on the availability of parts and their compatibility.

4. Marine and Aerospace

These industries depend on accuracy. EPCs offer detailed technical information and traceability, assuring security and compliance.

The Advantages of Using the Electronic Parts Catalogue

An EPC has several advantages for businesses as well as customers:

1. Improved Accuracy

EPCs assure precise identification of components through real-time data as well as detailed visual diagrams. This reduces the chance of human error and also prevents the ordering of parts that are not correct, thereby saving time and money for businesses.

2. Faster Parts Identification

Through advanced filtering options, categorisation of listings, and even 3D visualisations, users are able to find the item they require quickly. This simplifies the search process and dramatically improves the efficiency of service teams.

3. Reduced downtime

Technicians and dealers are able to instantly identify and order parts, eliminating delays caused by the manual search or confusion over stock. This means that repairs and maintenance can be accomplished faster, increasing overall efficiency.

4. Cost Efficiency

EPCs can reduce costs by eliminating the need for catalogues printed on paper as well as manual documents. Automating data management also lowers labour and administrative costs.

5. Seamless Integration

Modern EPC systems seamlessly integrate with CRM, ERP and e-commerce platforms, making sure that data is synchronised in real-time across departments. This results in a more unified workflow that helps in making better decisions and managing inventory.

6. A Better Customer Experience

Customers are able to easily search to check availability or buy parts on the self-service interface. This improves customer satisfaction, lowers the need for support personnel, and speeds up the entire buying process.

The Challenges of EPC Implementation

Despite their benefits, EPC deployments may face difficulties:

- Data Standardisation: Unconformity or out-of-date data on products can lead to mistakes.

- Integration complexity: Connecting EPCs with ERP systems that are older can be lengthy and time-consuming.

- Instructional Requirements: Personnel must be taught to utilise EPC tools effectively.

- Initial Costs: While the long-term benefits are significant, the initial setup and customisation will require an initial investment.

But these issues are usually offset by the system’s ROI over time and increased efficiency.

How to choose and implement an EPC

Selecting the best EPC requires assessing your company’s requirements. Choose scalable solutions that have robust integration options and user-friendly interfaces. Vendors such as PTC or Documoto provide customised platforms.

The implementation begins with data migration from catalogues that are already in use, and then the training of staff. Cloud-based EPCs help reduce the cost of IT by offering regular updates.

Future of EPC Systems Future of EPC Systems

EPC Technology continues to advance. Next-generation EPCs will likely rely on:

- AI as well as Machine Learning: To recommend parts compatible with each other and forecast the maintenance requirements.

- 3D visualisation as well as Augmented Reality Integration: To allow for immersive product exploration.

- Cloud-Based Platforms: for global access and scaling.

- Blockchain Integration: to improve traceability and authenticity.

These advances are expected to make EPCs even more critical in supply chains of the future and service operations.

Final Thoughts

The Electronic Parts Catalogue (EPC) is more than an electronic replacement for manuals printed on paper. It’s an empowering tool that links information, systems and users within an integrated ecosystem.

With the adoption of EPC technology, companies can increase efficiency in their operations, reduce human errors and offer quicker, more efficient, secure service to their customers.

As the world continues to become more digital, EPC systems will remain at the core of intelligent parts management, ensuring that the right piece is delivered to the correct location at the right time.

FAQS

1. What exactly is the definition of an Electronic Parts Catalogue (EPC )?

An Electronic Parts Catalogue (EPC) is a system of digital technology that assists dealers, manufacturers and service centres to manage and get detailed information on parts as well as assemblies and other products. It replaces printed catalogues with an online, interactive platform that delivers live updates and also integrates with other systems.

2. What exactly is an EPC function?

An EPC is a system that collects and organizes component data, which includes images, specifications, diagrams, and descriptions to create searchable databases. Users are able to quickly find the right parts, browse, and purchase the correct components with the help of part numbers, keywords or exploded diagrams, and the information is synchronized in real-time with software for CRM or ERP.

3. What industries make use of electronic parts catalogues?

EPC systems are widely used in automotive, agriculture, industrial equipment, aerospace, and marine industries–essentially anywhere parts identification and maintenance are critical.

4. What are the primary advantages of having an EPC?

EPCs enhance accuracy, cut the time to repair, cut down on operational expenses and increase customer satisfaction. They also seamlessly integrate with CRM and ERP systems for more efficient operations and better management of data.

5. Can EPCs be adapted to different industries?

Yes. Modern EPC platforms are highly customizable and can be customized to meet the specific needs of an industry, such as unique part numbers and pricing models, branding and integration with other systems.

6. What is the best way to make an EPC enhance customer service?

EPCs have self-service options which allow clients to look up, verify availability, and even order parts on the internet instantly. This helps reduce the need for support personnel and provides quicker, more efficient service.

7. Is an EPC system costly to implement?

The cost of initial setup varies according to how complex the integration requirements and data volume are. However, the majority of companies are able to recover their investment in a short time due to improved efficiency, fewer errors, and reduced time.