Automobiles are a worldwide system of interconnected manufacturers, suppliers, logistic providers, and dealers. Managing this complex and vast system requires coordination, precision and transparency at every level. It is at this point that the Role of EPR in Automotive Supply Chain becomes crucial.

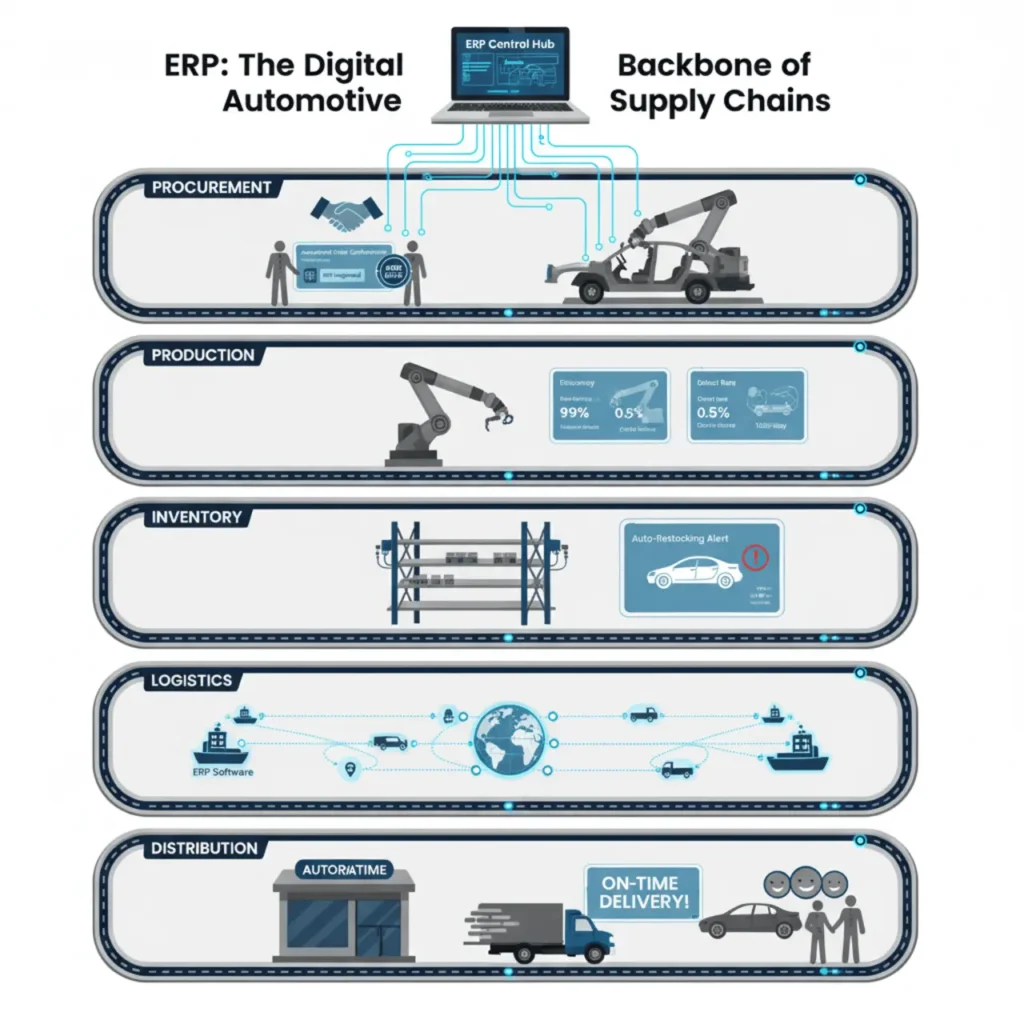

Enterprise Resource Planning (ERP) systems function as the electronic backbone that connects all the moving parts of an automotive supply chain – from the sourcing of raw materials and production planning through to distribution and inventory management. Through integrating several operations in a single, synchronised software platform, ERP aids suppliers as well as manufacturers to gain greater transparency, quicker decision-making, and better efficiency. In the age of information and automation, ERP is no longer simply a software program. It’s the basis for a more intelligent, connected, and more connected future for the automotive industry.

Understanding ERP for the Automotive Industry

In the automotive industry, ERP systems act as the digital backbone that connects various departments and suppliers. They consolidate information across warehouses, production lines, and distribution facilities, which allows companies to manage their operations more effectively.

A car-related ERP system typically encompasses:

- Warehouse Management and Inventory

- Procurement and Coordination of Suppliers

- Production Planning as well as Scheduling

- Marketing and Distribution

- Finance and Accounting

- Quality Control and Compliance

By bringing all these processes under one roof, ERP helps eliminate silos and facilitates collaboration between business divisions.

How ERP Unifies the Automotive Supply Chain

1. Centralised Database and Real-Time Accessibility

One of the main issues in supply chain management for automotive is the fragmentation of data. Logistics partners, suppliers, and dealers frequently utilise different systems that do not communicate effectively. ERP is a system that integrates the various systems, creating an unifying source of truth for all stakeholders.

Real-time data access enables proactive decision-making. For instance, if there is a delay in the shipment of raw materials, ERP alerts the production team immediately, allowing them to schedule operations again or search for alternative suppliers.

2. streamlined production and inventory management

Manufacturing of automobiles is heavily dependent on accuracy and timing. Any delay in one area of the manufacturing line could cause disruption to the whole assembly process. ERP systems help optimise material requirements Planning (MRP) by monitoring the level of inventory, forecasting demand, and automating purchases.

This will ensure that the correct materials are on hand in the appropriate timeframe, which reduces overstocking and decreases production idle time.

3. Better Collaboration with Suppliers

ERP improves supplier relationship management through more efficient communication and tracking of performance. Vendors can easily change their status via portals to suppliers, giving real-time information about the status of their material and the progress of shipment.

This transparency does not just increase confidence but also cuts down lead times and eliminates mistakes in the process of fulfilling orders.

4. Higher Qualitative as well as Compliance Management

The auto industry has to meet strict quality and regulatory requirements. ERP systems include quality control checks throughout the entire manufacturing and supply chain activities.

By analysing warranties and information on compliance in real-time, ERP helps companies maintain high standards of quality while avoiding costly recalls or fines from regulatory authorities.

5. Optimised Logistics and Distribution

Effective distribution is vital to fulfilling customer requirements and reducing the cost of transportation. ERP systems work in conjunction seamlessly with Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) to track shipments, oversee routes, and track the delivery performance.

This integration allows for a smooth flow of goods that are finished from the factory to the dealership and also ensures accurate fulfilment reports.

6. Profitability and Cost Reduction

Automating manual processes to eliminate redundant processes and increase confidence in forecasts, ERP drastically reduces operating costs. In addition, it assists businesses in identifying areas that are inefficient, such as production bottlenecks, stock shortages, or inefficient resources.

As time passes, these improvements will result in better profits and an advantage in the market.

Benefits of ERP in the Automotive Supply Chain

| Benefit | Description |

|---|---|

| End-to-End Visibility | Provides a unified view of operations, from procurement to distribution. |

| Data Accuracy | Reduces errors by centralizing data and eliminating duplicate entries. |

| Operational Efficiency | Streamlines workflows, minimizing manual intervention. |

| Agile Decision-Making | Enables faster response to disruptions or changes in demand. |

| Better Customer Satisfaction | Ensures on-time deliveries and high-quality products. |

| Compliance and Traceability | Maintains transparent records for audits and regulatory requirements. |

Real-World Impact

Automobile giants such as Toyota, Ford, and BMW use ERP software that has unified their supply chains throughout the world. They can keep track of inventory levels across different locations and coordinate production schedules, and swiftly adapt to market shifts.

Small to mid-sized automotive parts companies can benefit from the adoption of ERP. Automating repetitive tasks, like invoice processing and order processing, the company can concentrate on customer service and innovation.

The Key Features to Look For in Automotive ERP Systems.

When selecting an ERP solution specifically for the automotive industry, businesses should be looking for:

- Scalability: The ability to expand as operations expand.

- Cloud Integration: Access in real-time from various places.

- AI as well as Analytics: predictive insights to forecasting demand and managing risk.

- Modification: Modules tailored explicitly to automotive production, along with supply chain workflows.

- Connectivity Capabilities: Connectivity seamless to other systems, such as CRM and PLM.

The future of ERP in the Automotive Industry

The future of ERP in the automotive supply chain is within technological advancement and the intelligent use of automation. With the advent of IoT, AI, and blockchain, ERP software is becoming intelligent, secure, and connected.

IoT sensors provide the real-time tracking and monitoring of parts that are in transit, while AI analyses patterns to avoid interruptions. Blockchain provides an additional layer of trust and transparency by establishing permanent supply chain records that cannot be changed.

In the years ahead, ERP will evolve from an application for process management to a strategic decision-making centre and will help create higher-performance, more robust automotive ecosystems.

Final Thoughts

The importance of ERP in the Automotive Supply Chain goes well beyond the operational aspect. It is an innovative change in how automotive companies collaborate, develop and provide value. By bringing all elements of the supply chain into one digital platform, ERP eliminates silos, increases coordination, and enables the use of data-driven decisions.

From enhancing the accuracy of production to enhancing relationships with suppliers and logistics, ERP empowers the entire automotive industry to function as a single unit. As the automotive industry continues to develop with the help of technologies such as AI, IoT, and blockchain, ERP will remain the primary driver of flexibility, sustainability, and competitiveness within the global supply chain for automotive components.

Frequently asked questions (FAQs)

1. What exactly is ERP in the automobile industry?

ERP (Enterprise Resource Planning) is a computer system that integrates the most critical business functions, including manufacturing logistics, finance, supply chain, and sales–on one platform that streamlines operations in the auto industry.

2. How can ERP help improve the efficiency of supply chains?

ERP gives real-time visibility, automates workflows, and connects all stakeholders, decreasing mistakes, delays, and redundant processes in the supply chain.

3. Do small car manufacturers gain from ERP?

Yes. Cloud ERP systems are economical and adaptable, which makes them ideal for mid-sized and small automotive providers.

4. What are the main elements of an ERP for an automotive system?

Essential modules include inventory management, procurement planning, production planning and quality control, finance, and logistics.

5. What’s the future for ERP for the automobile industry?

The future is in AI-driven predictive analytics that are driven by AI, IoT integration to monitor real-time, and blockchain technology for transparency in the tracking of the supply chain.