In the machinery and automotive industry, the Electronic Parts Catalogue (EPC) has become a game-changer, changing the way dealers, workshops, and distributors find the spare components they require and how they manage them.

I’ve worked in the cloud-based and local EPC systems for more than 10 years in the field of automotive technology. I’ve witnessed in person how these two models work in real-world settings. Both have advantages, but also their weaknesses.

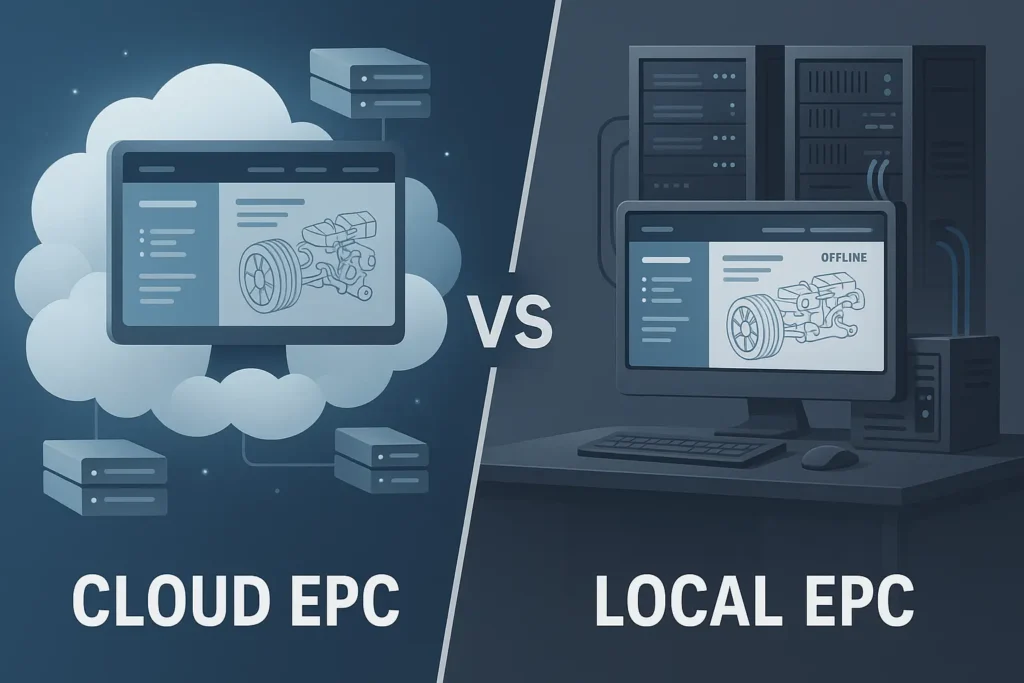

Let’s dive into the cloud EPC vs. Local EPC debate and discover which one best fits your company.

What is an EPC System?

An Electronic Parts Catalogue (EPC) is a digital solution that allows users to find, browse, and purchase spare parts with accuracy. Instead of having to flip through hundreds of printed sheets, EPC users can instantly identify the correct part number and diagrams, as well as compatibility information and costs.

In my work with car dealerships as well as service centres, the switch over from paper orders to EPC has helped reduce errors on orders by as much as 40% and has increased the efficiency of technicians significantly.

What is a Cloud-Based Electronic Parts Catalog?

Cloud-based EPC is stored on remote servers and is operated by a third-party service accessible through the internet using mobile or web browsers. This model of deployment makes use of cloud computing to save vast quantities of information about components, including specifications, prices, images, and availability. Users can log on from any location, workshop offices, or other remote locations–to search or view 2D/3D exploded diagrams by using hotspots. They can also manage orders and track shipments.

Example:

Dealers who use OEM platforms such as Ford’s and Toyota’s EPCs benefit from real-time updates, which ensure they have access to the most recent information about parts.

What is a Local (On-Premise) Electronic Parts Catalog?

Local EPC or on-premise can be installed on the company’s internal servers or personal computers. The entire data is stored in the company’s network and requires special hardware, software licences, and maintenance of IT. The catalog is accessible to users via local applications, usually restricted to local devices.

Example:

At one workshop that I worked on in 2015, we utilized a DVD-based, local EPC. It was a great solution; however, they had to install manually the latest data every quarter, which often took a long time and interrupted the operation.

Cloud Based EPC System: Pros and Cons

Cloud EPCs are gaining popularity because of their versatility and contemporary features. According to market analysis, cloud deployments allow immediate updates and central data management, which are essential in industries that have rapidly changing inventories. This article will provide a balanced view of their benefits and drawbacks.

Pros:

- The ability to scale and flexibility: You can easily scale your users and storage when your business expands without having to invest in new hardware. This is ideal for expanding OEMs and dealers dealing with seasonal spikes in demand.

- Accessibility as well as collaboration: Accessibility to any device connected to the internet, which allows remotely-based work and teams, as well as real-time collaboration. Technicians can utilize mobile apps to perform on-site identification of parts using visual search or AI-based queries.

- Cost-Effectiveness: Lower initial costs associated with subscription-based rates (e.g., pay-per-user). There is no need to invest in expensive servers or IT infrastructures; providers take care of maintenance and upgrades.

- Automated Updates, Integration: Real-time data synchronization, supersession management, data syncs, and integrations with CRM, ERP, or e-commerce platforms can simplify workflows and reduce errors.

- Enhanced features: The features are often accompanied by AI tools such as natural search in languages (“Show brakes to Model X”) and image enhancement to create better images, increasing efficiency by as much as 35-50 percent in case studies of industrial and automotive sectors.

- Disaster recovery: Built-in backups and redundancy guarantee the availability of data, making recovery easier as compared to manual processes on-site.

Cons:

- Internet Dependency: Requires a stable connection, and outages could stop access, although offline modes can mitigate this.

- Security Risks: The storage of data off-site can be vulnerable to breach, even though trusted providers utilize encryption and compliance standards such as GDPR.

- Continuous Costs: Subscription charges will increase over time, over and above one-time local purchases, to ensure reliable operations.

- More Control: Rely on the provider for uptime and customizing Performance. It may differ depending on the speed of the internet.

Local (On-Premise) EPC System: Pros and Cons

Local EPCs give you a sense of control and security in controlled settings, but have a higher cost for management.

Pros:

- Information Control and Security: Full control of data stored on internal servers reduces external risks and guarantees that the data complies with the strictest guidelines. It is ideal for highly sensitive industries such as aerospace.

- No Internet required: It is a non-Internet service that operates offline, allowing for consistent connectivity to areas of low or no connectivity with no latency issues.

- Customization: It is easier to customize to meet specific needs, without limitations from the provider, like the integration of proprietary tools.

- One-time Costs after initial investment, there are no ongoing fees; the budget is predictable for use over the long term.

- High Performance: Low latency for on-site users, as well as rapid fixes for issues, as everything is handled internally.

Cons:

- High-Upfront Costs: Major expenses for software, hardware licenses, installation, and IT personnel.

- Limits Scalability: Scaling involves additional hardware and setups, which can take a long time and be expensive.

- Maintenance burden: Organizations take care of updates, backups, and troubleshooting, diverting resources away from their core business.

- Accessibility issues: Limitation on local network access; remote connectivity requires VPNs, which can complicate global operations.

- Old Features Manual updates could result in inaccurate data, leading to a higher chance of errors in order part or supersessions.

Key Differences and Comparison

To aid you in your decision for yourself, here’s a side-by-side comparison with a table to help you decide:

| Aspect | Cloud EPC | Local EPC |

|---|---|---|

| Deployment | Hosted on remote servers; internet-based | Installed on internal servers/computers |

| Cost Structure | Subscription (low initial, ongoing fees) | High upfront, lower long-term |

| Scalability | High; on-demand resources | Low; requires hardware upgrades |

| Accessibility | Anywhere with internet; multi-device | Limited to local network; on-site devices |

| Security | Provider-managed; potential third-party risks | Full internal control; higher privacy |

| Updates | Automatic and real-time | Manual installations |

| Integration | Easy with APIs/ERP/CRM | Custom but potentially complex |

| Backup/Recovery | Automated and redundant | Manual; requires on-site infrastructure |

Cloud EPCs are an excellent choice for dynamic environments that require collaboration as well as rapid scaling. Local versions are ideal for businesses that value control and reliability offline.

Advantages of Cloud EPC

1. Access Anytime, Anywhere

When I set up a cloud-based EPC for a multi-city dealership chain, the teams of employees could now use the same catalog from multiple branch locations with no data clashes. This significantly decreased duplicate orders as well as improved coordination.

2. Automatic Updates (No More Manual Updates)

Cloud EPCs allow updates to occur automatically and over time in the background. One of the companies I spoke to was able to devote one day a month to updating the local EPC information. After the move to the cloud, it was no longer the case.

3. Lower IT Overhead

Cloud EPCs remove the requirement for costly server locations or dedicated IT staff. All maintenance, patches, and security-related tasks are managed by the provider, which is ideal for small – to medium-sized companies.

4. Scalable and Flexible

If you’re a small repair shop or a huge dealership, cloud EPC solutions are scalable in accordance with your requirements.

5. Data Backup and Security

Cloud providers that are leading in their field use sophisticated encryption and backup techniques to safeguard your data from hardware failures or loss.

Disadvantages of Cloud EPC

- It requires a reliable internet connection

- Information is backed up off-site. This could create privacy issues for some companies.

- Subscription costs can build up over time.

In one instance, the client in a rural location was confronted with constant connectivity issues, which forced them to switch to their previous local EPC temporarily.

Advantages of Local EPC

1. Full Control Over Data

Local EPCs offer total control over data storage, access, and updates. Companies that have strict data privacy policies typically opt for this type of system.

2. Works Without Internet

Local EPCs can operate entirely offline, which is perfect for workshop spaces in rural locations or areas with weak internet connections.

3. Faster Response Time

Because all information is saved locally, all diagrams, parts, and information load immediately without delay on the network.

Disadvantages of Local EPC

- Initial setup and maintenance cost

- Manual updates can be lengthy.

- Teams that work remotely

- Hardware failures could lead to the loss of data when backups aren’t properly maintained

An actual example is that one dealer chain was home to five distinct EPC installations. The syncing of updates across all of them resulted in frequent versions not matching.

Which One is Better? Factors to Consider

The two aren’t necessarily “better”-it depends on what you need. For growing or new businesses, cloud EPCs are affordable and flexible as they reduce the number of errors in orders by 40 percent for automotive studies, and increase sales by utilizing e-commerce. Cloud EPCs are ideal for international operations, remote teams, or for industries like EVs in which rapid changes are crucial.

Local EPCs are best for companies with stable demand and high security requirements or a limited internet connection, allowing cost savings to support reliable demands. Take into consideration your company’s size (small prefers cloud) and budget (cloud for lower cost of capital), as well as industry-specific regulations (local to meet compliance) and growth plans (cloud to increase scalability). Hybrid models, which combine both, are gaining popularity for well-balanced benefits.

Finally, test using a trial or a consultant to make sure it is compatible with your workflow.

Which EPC System Should You Choose?

It’s a matter of choosing the right option between cloud EPC and Local EPC, which is based on your company’s size, infrastructure, workflow, and. Here’s how to make the right choice:

Choose Cloud EPC If:

- You’re looking for flexibility and remote access.

- You like automated updates and low maintenance.

- You have a reliable internet connection.

- You’re in search of an affordable, scalable, and cost-effective program.

Choose Local EPC If:

- Your business needs absolute data security.

- You are in a region with a limited internet connection.

- You already have an IT infrastructure.

- You require a reliable offline connection throughout the day.

Based on our experience, 70% of modern dealerships are currently shifting to cloud EPC platforms and cloud EPC systems, whereas locally-based EPCs are still common in older businesses or industries with a high degree of restriction.

Future Trends: The Rise of Cloud-Based EPC Systems

The trend across the globe is evident: Cloud EPCs are the future.

Manufacturers are now integrating AI-driven search as well as 3D visualization and predictive parts ordering, all of which are made possible by the cloud. However, the process of maintaining several variations of locally-based EPCs becomes more costly and not feasible.

Most businesses find that moving to a cloud-based EPC isn’t only an upgrade, it’s an investment that will last for years in effectiveness and scaling.

Final Thoughts

In my experience of working in both EPC and non-EPC models, the conclusion is evident:

- If you are looking for speed, automation, and cooperation, Cloud EPC beats the competition hands down.

- If you are looking for the accuracy of your data as well as offline stability, Local EPC is still a good option.

The most effective EPC solution is one that is compatible with your business needs, as well as internet reliability and the data policies. In the future, however, it appears that the cloud computing model is quickly becoming the standard in the manufacturing and automobile industries across the globe.

FAQs

What is the primary difference between local and cloud EPCs?

The most significant difference is cloud hosting. Cloud is remote and accessible via the internet to allow for flexibility, whereas local is on-site to control and offline usage.

Are cloud EPCs more secure than those that are local?

Local is not the only option; it offers greater control, however, cloud providers make considerable investments in security. Evaluate your compliance requirements.

How are costs compared to long-term?

Cloud is less expensive in the beginning; however, it is a recurring cost. Local costs more upfront, but is cheaper over the course of 5+ years to ensure steady usage.

Do I have the option of switching the cloud from my local EPC?

Many providers provide tools for migration, but they require data transfer as well as education.

Which is the best option for small-sized companies?

Cloud EPCs are a result of their scalability and lack of hardware requirements, making they accessible to entrepreneurs.

Do cloud EPCs allow offline access?

Some include offline modes that have cached data that syncs as soon as online, making them ideal to use in the field.

Which industries are most benefited by cloud EPCs?

In construction, auto, and aerospace, live updates in real time and access via mobile devices can reduce the amount of downtime.