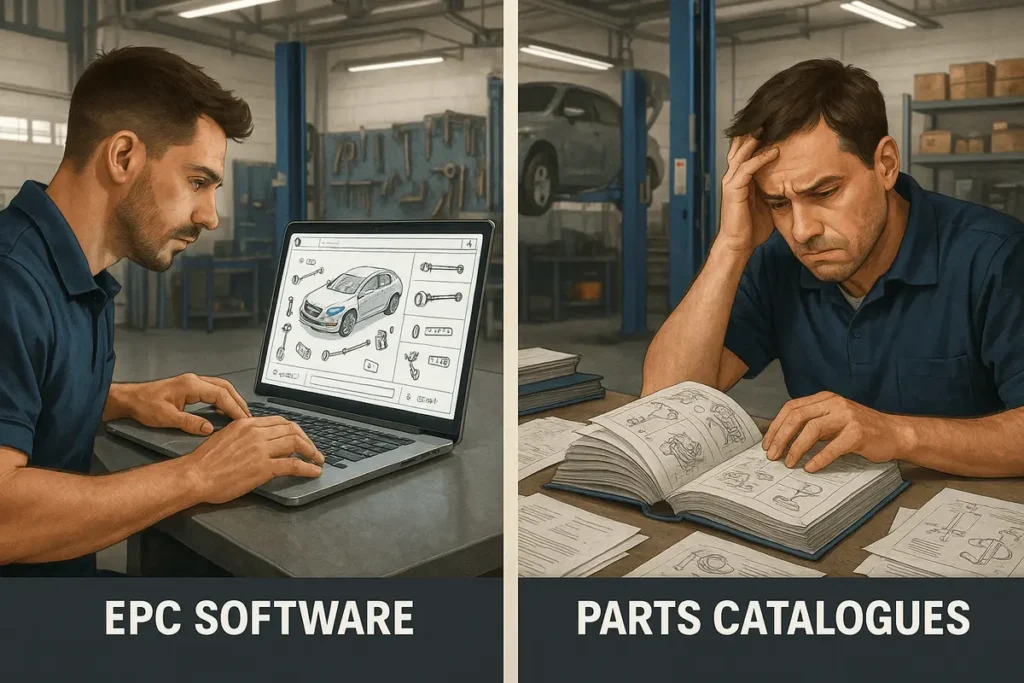

I’ve witnessed the auto repair industry flip between analogue and digital much faster than an engine spool-up. In the past, I would carry the heavy traditional catalogues of parts as if the bible of my life; however, now? EPC software has almost replaced my shop. If you’re like me and are looking to decide if it’s the right time to trade in papers for pixels or are interested in the hype, then you’re in the right place.

This article will look at EPC software vs Traditional Part Catalogues, in simple English.

I’ll tell stories from my workshop, outline the major differences, and then add a few pros and cons that can help you choose. It’s going to be casual, as if we’re talking about coffee at the breakroom.

What is EPC Software?

EPC is an acronym for Electronic Parts Catalog. Think about it like a hyper-charged digital database for car parts. It’s a program (often cloud-based or mobile-style) that allows you to look up parts by using VINs, model/make/year, and even words. It provides three-dimensional views, exploded diagrams, as well as pricing and ordering hyperlinks. From my experience, tools like those from ALLDATA or manufacturer-specific ones (Ford, GM, etc.) are lifesavers. They’re interactive, they update in real time, and are able to integrate into your shop’s inventory system.

Contrary to what was used in the past, EPC isn’t static–it’s alive and well with features like VIN decoding to ensure that matches are spot-on.

What is Traditional Parts Catalogues?

Ah, the great old days or were they?

Parts catalogues of the past are bound books, printed books, or even PDFs that are filled with lists, diagrams and parts numbers. You’d flip through pages or cross-reference the indexes, and hope that the information was not outdated. I can remember the first day I worked there: a huge catalog from vendors such as NAPA or O’Reilly and O’Reilly, each one larger than the thickness of a steak. They’d be published annually, and by the time they were halfway through, half the pages had changed.

They’re simple, no tech is required. However, they get dusty and are a nightmare to use. They’re great for backups but not suitable for daily tasks.

Head-to-Head Comparison: Where EPC Software Vs Traditional Parts Catalogues

Let’s put them against one another like the drag race. I’ll use my own shop experiences and also the things I’ve observed work (or fail). Based on what experts are saying, EPC software blows traditional catalogues off the mark in a lot of areas, but it’s not always single-sided.

1. Speed and Efficiency: Digital Wins Hands Down

The old catalogues? You’d be spending hours (or hours) flipping through pages to find just one item. I once squandered half an hour searching for the fuel pump relay within the pages of a book with a dog’s paws.

EPC software? Enter the information and you’ll get results in just a few minutes. Interactive diagrams and search in real-time allow you to zoom, rotate and even click to get more information. This is a huge benefit for my store, as I can finish tasks quickly and allow more customers. The guide I read states that EPC lets you quickly look up information, which reduces wait times to a great extent. It’s like converting from a bicycle to a motorbike to improve your workflow.

2. Accuracy and Precision: No More Guesswork

With catalogues made of paper, mistakes occur, such as incorrect part numbers, obsolete specifications, or fuzzily drawn illustrations. I’ve had gaskets that aren’t matched more times than I’d prefer, which has led to return orders and angry customers.

EPC increases its efficiency by ensuring precise identification of parts by VIN codes and 3-D drawings. It recognizes supersessions (updated parts) and compatibilities on its own. Based on my experience with fixing imports, such as Subarus, the accuracy of this program has cut my errors by at least 50 percent. Plus, it’s manufacturer-verified, so you know it’s legit.

3. Updates and Freshness: Stay Current Without the Hassle

The old catalogues wear out like milk. Print one, and then they’re obsolete shortly thereafter. You’d receive supplements or even updated editions, but keeping them up was a hassle. I had piles of errata sheets piled up on my work area.

EPC software is able to pull updates directly from the cloud. Recalls, new components or price changes are all there without having to lift a finger. In the midst of supply chain turbulences and other times, my EPC enabled me to switch to new options fast. It’s also future-proof, particularly with the rapid evolution of the auto industry.

4. Cost Savings: Payoff in the Long Run

The initial cost of traditional catalogues is affordable. You only need to buy one, and then use it for years (until the catalogue is no longer needed). But what about time loss and mistakes? They will cost you directly.

EPC could have subscription charges ($50-$200/month). However, it can lower costs by speeding up the process and reducing returns. According to one source, it cuts out middlemen and reduces costs. In my shop, it was paid for over a period of months by creating more jobs. For small businesses, it’s an investment worth making.

5. Technology and Usability: Features vs. Tactile

Traditional ones are tactile. You can make notes on them. No internet? Problem solved. But the search is a manual process and has limitations.

EPC is user-friendly, with filters, a search bar and integrations (like placing orders directly to suppliers). Additional features like mobile apps mean I can access parts underneath the car. The downside is that it requires tech expertise and an internet connection. But, hey, if I can master it at the age of 50 or less, everyone can.

6. Collaboration and Training: Teamwork Makes the Dream Work

Catalogues of paper are a solo act and difficult to duplicate without photocopying.

EPC permits multi-user access, annotations and simple sharing. I’ve utilized it to train learners using diagrams on screen. It’s boosted my team’s efficiency, turning rookies into pros quicker.

Advantages of EPC Software

- Quicker repairs: Technicians will have less time looking for the right parts, thus reducing the time spent on repairs.

- Accurate orders: minimizes incorrect part orders, reduces the number of returns and complaints from customers.

- Cost Saves: It reduces time spent on labour as well as errors and management errors.

- Improved Collaboration: Teams from dealerships, workshops, as well as distributors are able to access the same data in real-time.

- Scalability: It can easily accommodate new car models and components when manufacturers issue updates.

Challenges of Traditional Parts Catalogues

Although traditional catalogues may be helpful in low-tech settings, they pose a number of challenges:

- Old Information: Part numbers change often, and outdated catalogues could result in errors.

- Limited access: Physical books or PDFs cannot be shared with several users.

- Labour-intensive: Staff members have to manually check the compatibility of parts, which can slow down the operation.

- Error-Prone: Manual entry increases the chance of making errors.

Who is the most benefits the Most from EPC Software?

- Workshops and mechanics: Reducing time on finding parts and improving the efficiency of repairs.

- Dealerships: Enhance customer satisfaction with speedier service and more accurate parts sales.

- Parts Distributors: Optimize the management of inventory, minimize stock-outs, and reduce returns.

Implementation Tips for EPC Software

- Select Cloud-Based Solutions: Cloud EPC systems provide instant updates and access to multiple devices.

- Train staff: Training is essential to ensure that technicians and part managers are able to make use of advanced search capabilities and feature compatibility effectively.

- Integration With Inventory Systems: Linking EPC software to stock management makes it easier to manage orders and decreases the chance of errors.

- Periodic Updates: Make sure that the software is updated by the manufacturer to ensure precision.

EPC Software vs Traditional Catalogues: ROI

Even though EPC software is often sold with a cost for subscription but it is worth the returns on investments (ROI) is significant:

- Lower labour costs because of more efficient search results.

- Lower cost of carrying inventory because of accurate inventory management.

- There are fewer customer complaints and fewer returns.

- Improved overall productivity and increased customer satisfaction.

Over time, the digital EPC systems are able to pay for themselves through boosting efficiency and decreasing errors. While traditional catalogues are less expensive upfront, they will also incur additional operational costs that are not apparent.

My Personal Experience: Why I Switched and Never Looked Back

It’s true that I was initially skeptical, I thought EPC was just an expensive technology for dealers. However, after a sloppy purchase from an old catalogue cost me a whole day’s worth of work, I decided to try the free trial. Game-changer! It’s now my go-to whenever I need routine service to custom build.

Yes, I have some paper copies to deal with power failures. However, the time, the digital governs. If you’re in a bustling business like mine, EPC cannot be a luxury; it’s mandatory in 2025.

Wrapping It Up: The Future Is Digital, But Know Your Needs

The EPC Software versus traditional part catalogues fight, digital claims the top spot for speed, as well as accuracy and efficacy. If you’re a fanatic or living in a remote area with a slow internet connection, paper is still a place. From my home to mine, consider giving EPC a try. It will ease your burden and make your business more efficient. Are you ready to upgrade? Find providers and start with a small one.

FAQs

What is the primary distinction between EPC software and traditional catalogues?

EPC can be digitally interactive, allowing quick updates and searches, while traditional lists print lists, which need manual navigation. EPC makes part-hunting an easy task, based on my everyday use.

Are EPC Software worth the price to independent mechanics?

In my experience, the time savings far outweigh the costs. It reduces mistakes and improves productivity, which results in more revenue.

Do traditional catalogues still prove effective in the present?

Yes, offline backups are possible even in simple shops. But they’re not as robust as EPC’s real-time capabilities.

How can I start using EPC software?

Select a company similar to ones that provide manufacturer information and enroll for a trial, and then integrate it into your software. I started with the basics, and then grew.

Does EPC work with all car models?

The majority of them cover the major brands and models, and some specialize in heavy equipment, automobiles and more. Make sure you are compatible with the model first.

Are there any negatives to going completely digital?

Internet dependence and a slight steep learning curve. However, the benefits more than outweigh the drawbacks in modern shops.