In the world of automotive repair, repair, and maintenance, time and cost are key elements. Electronic Parts Catalogue (EPC) software has changed the way companies handle spare parts by transforming conventional catalogues into interactive databases. They provide immediate access to complete information on parts like numbers, descriptions, compatibility pricing and images available across a range of devices. Through facilitating identification of parts order, controlling inventory, EPC software effectively minimises the cost of operations and reduces costs.

This article explains how EPC Software saves time and money that come with EPC software, backed by real-world case studies as well as experts’ analysis. It is an indispensable resource for forward-thinking workshops looking to improve productivity and efficiency.

Whether you’re a mechanic, shop owner, or OEM, adopting EPC can transform your operations

let’s dive into the details.

What is EPC Software?

EPC software is an electronic platform that stores, organises, and manages all equipment and product information about parts. It lets companies quickly find parts, verify availability, and generate precise parts numbers to order or for maintenance. In contrast to manual methods, EPC software integrates seamlessly with ERP systems, inventory management solutions and procurement workflows, which allows for quicker and more precise operations.

Key Features of EPC Software:

- Digital Parts Database: Centralised repository of every part and assembly.

- Search and Tool for Identification: Quickly identify parts by using diagrams, part numbers, and descriptions.

- Inventory Integration: The system syncs up with Warehouse Management Systems to monitor the levels of stock.

- Automated ordering: Creates purchase orders based on thresholds for inventory.

- Interactive diagrams and Manuals: Interactive tools to help identify and verify components.

- Reporting and Analytics: Provides insight into cost-saving strategies and inventory optimisation.

Understanding How EPC Software Works: A Quick Overview

EPC software is a revolutionary alternative to traditional catalogues printed on paper by offering an online platform that effortlessly connects to manufacturers’ databases. Innovative features such as VIN-coded and three-dimensional views speed up the process of identifying and ordering parts, which is particularly beneficial in areas like heavy machinery and automotive, where downtime can be costly. Through automation, EPC software boosts efficiency and minimises mistakes, ultimately making sure that there is no financial loss.

How EPC Software Saves Time and Money?

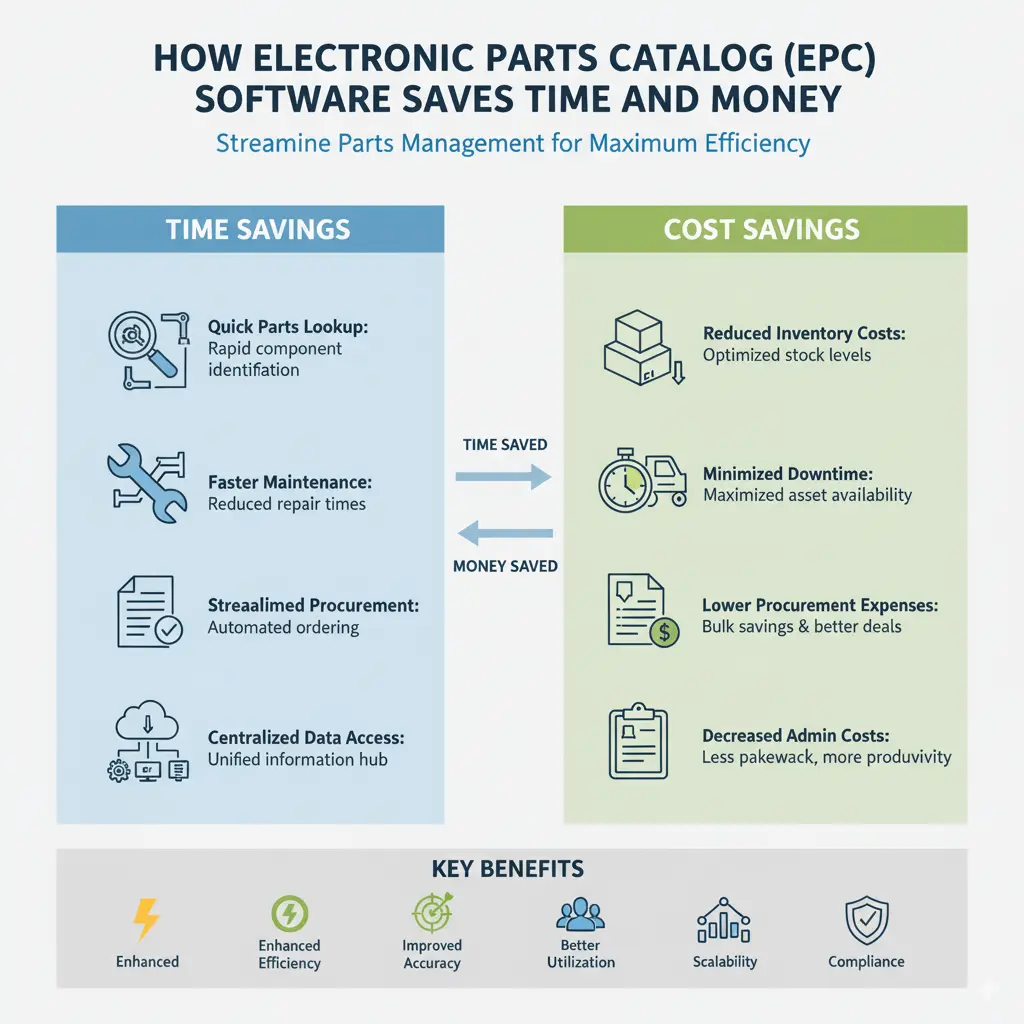

1. Key Ways- How EPC Software Saves Time?

Time Savings through EPC Software the most significant benefit that comes with EPC software is the significant time savings it offers through automation of the labour-intensive tasks of manual search and update.

1. Faster Parts Identification and Search

Traditional catalogues need turning pages or cross-referencing indexes and can take up to a minute per search. EPC software allows immediate searches with filters, keywords or visual diagrams, decreasing search time by as much as 80percent. for mechanics, this translates to faster diagnostics. Click to open a 3-D image and zoom into the components and check compatibility with no physical disassembly. In manufacturing facilities, technicians are able to identify components on the spot using mobile apps, which reduces downtime for machines and allows faster repairs.

2. Real-Time Updates and Automated Change Management

Incorrect information in catalogues results in wasted time and effort chasing parts that are no longer available. EPC systems automatically download updates from manufacturers, such as supersessions for items that are no longer in production and recall notices. This makes sure that users have up-to-date information, eliminating the delay caused by manual revisions. The system-wide synchronisation ensures that changes spread immediately across teams, thereby saving time on coordination.

3. Seamless Integration with Workflow Tools

Field technicians do not have to travel to the office for catalog access. Cloud-based EPCs offer mobile interfaces that can be offline-capable which allow for real-time parts lookups when remote repairs are required. This reduces the time spent traveling and waiting making it easier to keep operations moving along.

4. Mobile Accessibility for On-the-Go Efficiency

Field technicians no longer need to return to the office for catalog access. Cloud-based EPCs provide offline-capable mobile interfaces, enabling real-time part lookups during remote repairs. This mobility reduces travel time and wait periods, keeping operations moving smoothly.

5. Error Reduction

With accurate information and alerts to potential problems, EPC software prevents mistakes which could delay the project’s completion.

2. Key Ways- How EPC Software Saves Money?

Beyond time, EPC delivers direct financial benefits by cutting waste, errors, and overhead.

1. Reduced Errors and Returns

Ordering the wrong part is costly—returns, shipping fees, and rework add up. EPC’s precise tools, like VIN-based matching and 3D visualizations, minimize mistakes, with some users reporting a 40% drop in errors. Accurate identification ensures first-time-right orders, saving on labor and expedited shipping.

2. Optimized Inventory Management

Overstocking ties up capital, while stockouts cause delays. EPC software automates inventory alerts for low stocks and integrates with suppliers for just-in-time ordering. This prevents excess inventory costs and reduces holding expenses by maintaining optimal levels. Dynamic pricing modules adjust costs based on regions or tiers, maximizing margins.

3. Lower Operational and Maintenance Costs

By speeding up repairs, EPC reduces vehicle or machine downtime, which can cost businesses hundreds per hour. Automated warranty processing cuts administrative time, while online self-service portals for customers decrease support queries and staffing needs. Overall, shops see reduced labor costs and higher throughput.

4. Enhanced Aftermarket Sales and Revenue

EPC turns catalogs into e-commerce platforms, enabling direct online ordering and upselling related parts. This boosts aftermarket revenue without additional marketing spend. For OEMs, it streamlines dealer interactions, increasing sales efficiency and loyalty.

Benefits of EPC Software

- Enhanced Productivity: Teams work faster and smarter.

- Improved Transparency: Stakeholders have clear visibility into project progress.

- Risk Mitigation: Early detection of potential issues reduces project risk.

- Scalability: Software can handle multiple projects simultaneously without additional staff.

- Regulatory Compliance: Ensures projects meet industry standards and legal requirements.

Choosing the Right EPC Software

When selecting EPC software, consider these factors:

- Ease of Use: The interface should be intuitive.

- Integration Capabilities: Should connect with ERP, CAD, or other software.

- Customization Options: Adaptable to your project types and scale.

- Support & Training: Ensure vendor provides adequate support.

- Cloud vs On-Premises: Cloud solutions allow remote access and better collaboration.

Implementation Tips for Maximum Savings

To reap these benefits, choose EPC providers like Documoto or IntelliNet with strong integration and support. Start with staff training and a pilot program. Monitor metrics like order accuracy and turnaround time to quantify ROI—many see returns within months.

Conclusion

EPC software is a game-changer for saving time and money in parts management. By enhancing efficiency, accuracy, and integration, it cuts downtime, errors, and overhead while boosting revenue. In an era where operational agility is key, investing in EPC future-proofs your business against rising costs and competition. If you’re still using traditional methods, now’s the time to switch—explore EPC solutions to unlock these savings today.

FAQs

What is EPC software, and how does it work?

EPC software is a digital catalog for parts, using searches, visuals, and integrations to identify and order components efficiently, saving time over manual methods.

How does EPC software reduce search and identification time?

It provides instant searches, 3D views, and filters, slashing lookup times from minutes to seconds for faster repairs.

In what ways does EPC software cut costs?

By minimizing errors, optimizing inventory, and automating processes, it reduces returns, overstocking, and labor expenses.

Can EPC software help with inventory management savings?

Yes, automated alerts and real-time data prevent stock issues, lowering holding costs and waste.

How does EPC improve accuracy to save money?

Features like compatibility checks and updates reduce wrong orders, cutting return and rework costs significantly.

Is EPC software suitable for small businesses?

Absolutely; scalable options offer cost-effective subscriptions, with quick ROI from time savings.

What industries benefit most from EPC time and money savings?

Automotive, manufacturing, and heavy equipment, where downtime and errors are expensive.

How quickly can businesses see ROI from EPC software?

Many report savings within months through reduced errors and faster operations.