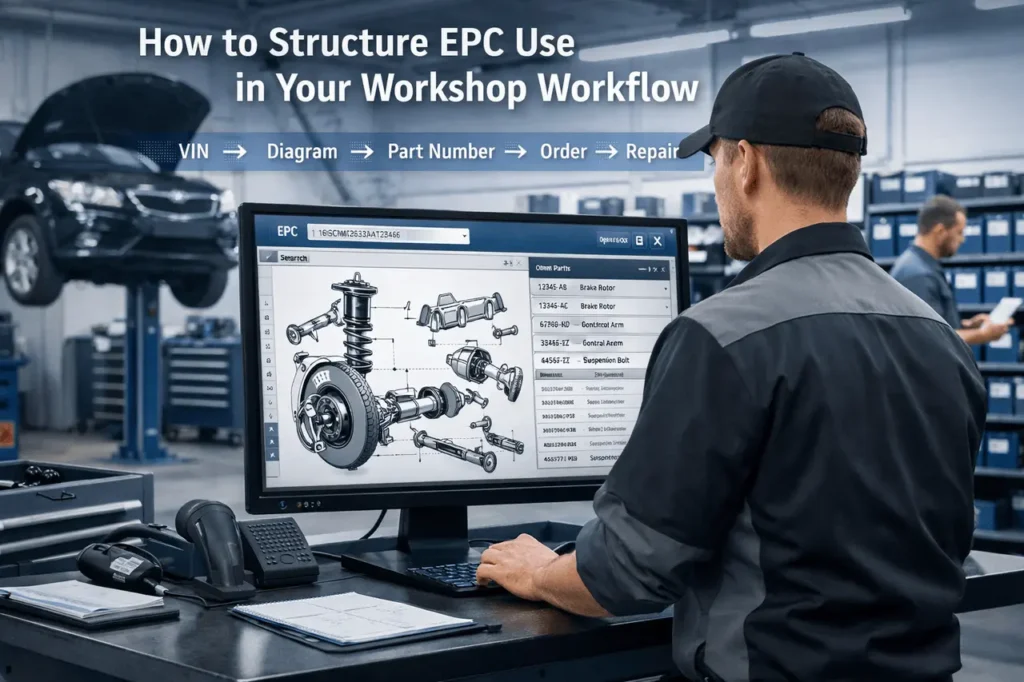

To plan EPC use to streamline your workshop workflow, you must incorporate EPC (Electronic Product Catalogue (EPC) in each stage of diagnostics, part identification, procurement, as well as job-related documentation. If properly structured, EPC systems reduce parts errors, increase turnaround time, and improve service consistency.

An Electronic Product Catalogue (EPC) is a digital database containing manufacturer-approved part numbers, diagrams, supersessions, and fitment data. In the automotive, heavy equipment, and industrial repair areas, EPC platforms are critical for ensuring accurate parts ordering and service planning.

This guide shows you Structure EPC Use in Your Workshop Workflow. how to integrate EPC usage into workshop activities to maximise efficiency.

What Is an EPC in a Workshop Context?

An Electronic Product Catalogue provides:

- OEM part numbers

- Diagrams of technical design that are exploding

- Car or equipment compatibility information

- Supersession and history of replacement

- VIN and serial-based filtering

In contrast to printed catalogues, EPC systems are regularly updated by manufacturers to reflect design changes and the removal of obsolete parts.

Why Structured EPC Integration Matters?

Workshops typically utilise EPC software to perform tasks only when the component is required. A structured approach integrates EPC usage into:

- Job intake

- Diagnostics

- Estimation

- Parts placing an order

- Repair validation

- Documentation

Key Risks of Unstructured EPC Use

- Incorrect part orders

- Duplicate ordering

- Delayed repairs

- Incorrect interpretation of superseded components

- Rejections of warranty claims

A defined EPC workflow minimises these risks.

Core Components of a Structured EPC Workflow

1. VIN/Serial-Based Job Intake

Begin each repair request by confirming:

- Vehicle Identification Number (VIN)

- Engine code

- Production year

- Modification and Trim Level

Entering VIN information into the EPC ensures accuracy specific to the model.

It helps prevent errors caused by changes in production during the same year as the model.

2. Diagnostic Confirmation Before Parts Lookup

Before making use of the EPC:

- Confirm fault codes

- Validate visual inspection findings

- Verify part failure

EPC systems offer diagrams, but they cannot diagnose. A catalogue search must precede diagnostics.

3. Structured Parts Identification Process

Adopt a standardised sequence:

- Locate system category (e.g., braking, cooling, electrical)

- Use the exploded diagram view

- Cross-check part number

- Confirm supersession

- Validate fitment restrictions

The assurance that parts aren’t chosen because of their visual similarity.

4. Cross-Department EPC Access

For maximum efficiency, allow:

- Service advisers should confirm the pricing of parts

- Parts managers need to verify the availability

- Technicians can see diagrams directly

Centralised access reduces bottlenecks.

Traditional vs Structured EPC Workflow

| Workflow Stage | Traditional Approach | Structured EPC Approach |

|---|---|---|

| Job Intake | Manual data entry | VIN-based EPC validation |

| Parts Search | After diagnosis | During estimation and validation |

| Supersession Check | Often missed | Mandatory step |

| Documentation | Separate from EPC | Linked to EPC reference |

| Error Rate | Higher | Reduced significantly |

The structured model incorporates EPC into every repair choice, not just the order.

How to Implement EPC Structuring Step-by-Step?

Step 1: Define Internal EPC Protocols

Develop documented processes that outline:

- When is EPC required?

- The person responsible is verifying EPC?

- How are supersessions handled?

- How are screenshots or references saved?

Standardisation ensures consistency across technicians.

Step 2. Integration of EPC to Workshop Management Software (WMS)

When it is possible, connect EPC devices to

- Workshop Management Systems (WMS)

- Dealer Management Systems (DMS)

- Inventory platforms

This allows:

- Automatic part number transfer

- Reduction of Manual entry error

- A streamlined method of billing

Step 3: Train Technicians on Diagram Interpretation

Misreading diagrams with exploded parts is a frequent problem.

Training should include:

- Component grouping logic

- Sub-assembly breakdown

- Production split indicators

- Specific to the market

Correct interpretation minimises the need for placing an order.

Step 4: Establish a Supersession Verification Rule

Supersession issues can cause compatibility issues.

Make it obligatory to:

- Check replacement chains

- Notes on compatibility

- Review manufacturer service bulletins

Supersession of documents within your job cards.

Key Benefits of Structuring EPC Use

1. Improved Parts Accuracy

VIN-based filtering guarantees a correct match between variants.

2. Reduced Repair Delays

Fewer incorrect orders mean fewer reorders.

3. Better Inventory Planning

Parts managers can identify:

- Commonly replaced components

- Seasonal patterns of demand

4. Stronger Warranty Compliance

OEM part traceability boosts claims approval rates.

Limitations and Challenges

While extremely powerful, EPC systems have constraints.

Data Update Dependency

Accuracy depends on manufacturer updates.

Subscription Costs

Several OEM EPC systems require paid access.

Learning Curve

Technicians require instruction to comprehend the catalogue structure correctly.

No Diagnostic Capability

EPC systems cannot replace scan tools or the service guides.

Knowing these limitations can prevent misuse.

EPC Use by Workshop Type

| Workshop Type | EPC Usage Focus | Workflow Priority |

|---|---|---|

| Automotive Repair | VIN-based parts matching | Speed and accuracy |

| Heavy Equipment | Serial-number validation | Model configuration tracking |

| Fleet Maintenance | Bulk parts planning | Preventive maintenance alignment |

| Dealership Service | OEM compliance | Warranty documentation |

Each environment needs a slightly different approach to structuring.

Best Practices for Long-Term EPC Optimisation

- Perform EPC workflow audits every quarter

- Review parts return rates

- Track incorrect order frequency

- Keep track of the version of the EPC software

- Archive part diagrams for completed jobs

Continuous monitoring improves operational uniformity.

My Final Thoughts

To effectively organise EPC use in your workshop’s workflow, integration should go beyond simple parts lookup. EPC systems must be integrated into job intake, diagnostics validation, order, and documentation procedures.

A systematic approach increases accuracy, reduces delays, improves the quality of warranty compliance, and aids better inventory planning. While EPC platforms require rigorous training and disciplined implementation, the operational benefits far outweigh the drawbacks.

As workshops continue to digitalise and become more structured, EPC workflows will remain vital to ensure efficiency, traceability, and technical accuracy in today’s service environment.

FAQs

1. What exactly does EPC mean in a workshop?

EPC stands for Electronic Product Catalogue. It is a manufacturer-provided digital database of parts and diagrams.

2. Why should workshops structure EPC use instead of using it occasionally?

Structured EPC use helps reduce parts errors, improve repair accuracy, and provide the same documentation across every job.

3. Is EPC used to replace manuals for service?

No. EPC offers part numbers and diagrams, but it does not provide complete repair procedures or diagnostic procedures.

4. What can VIN-based EPC lookup increase the accuracy of EPC lookups?

VIN input filter parts are specifically for a particular car’s production configuration, reducing compatibility errors.

5. Do technicians or part managers have the power to manage EPC access?

Both need to have access. Utilising cross-functional functions increases communication speed and reduces gaps.

6. Is EPC integration with the workshop software required?

Although not required, integration reduces data entry errors and enhances workflow efficiency.

Also Read –

AI-powered EPC Search: A Smarter Way to Find Electronic Parts