In today’s highly competitive manufacturing and automotive industries, efficient management of parts is crucial to efficiency and satisfaction with customers. Companies require quick access to precise product information, seamless catalogue updates, and robust integration with inventory or ERP systems. This is the place electronic Parts Catalogues (EPC) come in.

An EPC (Electronic Parts Catalogue) is a system of digital technology which organises, stores and displays information regarding spare parts, assemblies and the related components. It allows distributors, service teams and even customers to find and purchase the correct parts quickly.

As technology advances, EPC systems are deployed in various settings, Cloud, On-Premise and Hybrid, with each offering distinct advantages and disadvantages. This article will look at the different deployment options along with their benefits and the best way to select the most appropriate one for your needs.

This article explains the EPC deployment choice in detail and outlines its benefits as well as drawbacks and applications that can help users choose the most appropriate option for their business.

What is an Electronic Parts Catalogue (EPC)?

The Electronic Parts Catalogue is a digital product that can replace printed catalogues, either PDF or printed. It allows dealers, manufacturers and service centres to control and share information about parts in a dynamic manner.

A typical EPC comprises:

- Part and product information that is detailed

- Assembly drawings and diagrams with explosions

- Real-time inventory availability

- Options for pricing and ordering

- Integration Integration ERP CRM, ERP, as well as E-commerce platforms

For automotive, agricultural or industrial equipment, an EPC makes it easier to find the right component as well as place an order, while reducing the time and error.

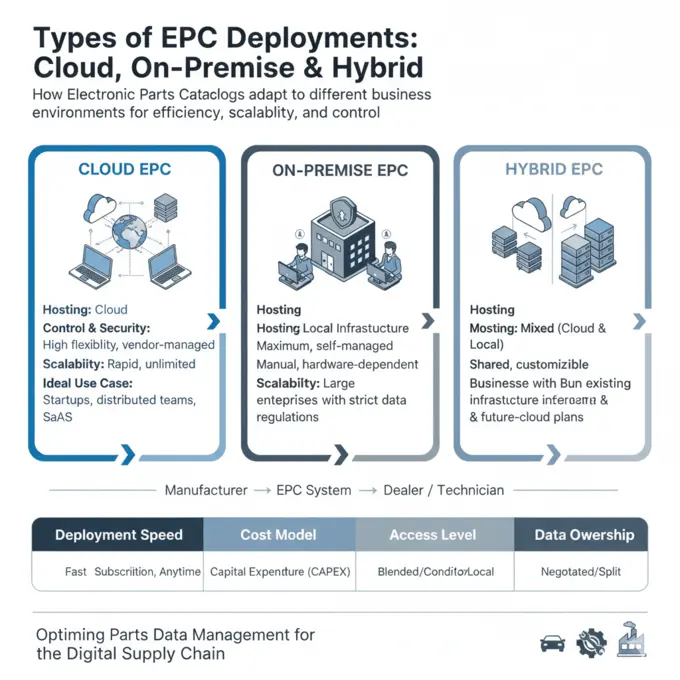

Types of EPC Deployments

EPC software can be used in three different methods: Cloud, On-Premise or hybrid. The best choice is contingent on the size of your business and IT capabilities, budget and the requirements for data protection.

1. Cloud EPC Deployment

Cloud-hosted EPC Systems are located on external servers and accessible via a browser on the web. The service provider is responsible for their infrastructure, upgrades and backups, which allows you to concentrate only on the program.

The Key Features:

- Web-based access is available from any place or device

- Version control and automatic updates

- User capacity

- Price based on subscription (SaaS model)

Advantages:

- Low costs for IT: No need for servers in the local area or for heavy maintenance.

- The ability to scale: Easily add new products as well as users or data as your catalogue expands.

- Global accessibility: It is Great for dealers or teams with distributed staff.

- Rapid installation: Get started within days, not weeks.

Challenges:

- Internet dependency: Requires stable connectivity.

- Privacy concerns for data: Sensitive product or pricing information that is stored off-site.

- Recurring cost: Long-term subscription may outweigh the initial licensing cost.

Best suited for:

- Small-to mid-sized companies

- Companies that have global dealer networks

- Businesses looking to set up quickly and require little or no IT management.

2. On-Premise EPC Deployment

The On-Premise EPC is hosted and installed locally on your local servers. You are the owner and manager of the infrastructure, assuring complete control over the performance and data.

Principal Features:

- Software locally installed and databases

- Direct control over updates, backups and access

- A high level of customisation, along with integration to internal systems.

Advantages:

- Full ownership of data: ideal for businesses that have strict compliance or a need for confidentiality.

- High-performance: Internal hosting eliminates dependence on external networks.

- Customised settings: Tailored integration with ERP, MMES, or other legacy systems.

- Cost efficiency over the long term: A one-time investment can be less expensive in the long run.

Challenges:

- High initial cost: Requires dedicated hardware and IT know-how.

- Maintenance responsibility: Updates, patches and backups need to be dealt with internally.

- Remote access is limited: Without further configuration, External users could face limitations.

Best suited for:

- Large OEMs or large manufacturers

- Companies with sensitive information or internal-only use

- Enterprises with strong internal IT teams

3. Hybrid EPC deployment

Hybrid EPC combines both cloud-based and in-house features and offers the flexibility of storage, access, and control. For example, sensitive part information could be stored on internal servers, whereas dealers can access catalogue information that is not confidential through the cloud.

The Key Features:

- Cloud-hosted front end for users from outside

- On-premise database to support internal systems

- Tools for synchronisation to ensure data coherence

- Flexible integration to ERP or PIM systems.

Advantages:

- The best combination of the two: Secure data control with remote access.

- Architecture that can scale: Cloud layer handles the growing number of catalogues or users.

- Resilience: Redundant systems minimise downtime risks.

- Access control tailored to the user role: Restrict or allow access to users based on their role.

Challenges:

- Complex configuration: Requires integration expertise and precise data synchronisation.

- Costs more at the beginning: Combines infrastructure from both environments.

- Complexity of management: Split responsibilities between IT and cloud service providers.

Best suited for:

- Enterprises with a mix of both external and internal stakeholders

- Global manufacturers that have dealers and confidential information

- Businesses that are transitioning from traditional on-premise to cloud-based modern solutions

Comparison Table: Cloud vs On-Premise vs Hybrid EPC

| Feature | Cloud EPC | On-Premise EPC | Hybrid EPC |

|---|---|---|---|

| Hosting | Vendor’s cloud infrastructure | Company-owned servers | Combination of both |

| Deployment Speed | Fast | Moderate to slow | Moderate |

| Data Control | Managed by provider | Fully owned by organization | Shared control |

| Customization | Limited | High | Moderate to high |

| Scalability | Very high | Limited | Flexible |

| Access Anywhere | Yes | Usually internal only | Selective (internal + external) |

| Cost Model | Subscription (OPEX) | License + Hardware (CAPEX) | Mixed (CAPEX + OPEX) |

| Best For | SMEs, distributors, remote users | OEMs, enterprises, secured networks | Global OEMs, hybrid environments |

Understanding the Nuances of EPC Deployments

Knowing the intricacies involved in EPC implementations is essential as businesses increasingly rely on digital technology to speed up time-to-recovery, increase the accuracy of parts ordering and aid in global supply chains.

For example, in the automotive industry, EPCs enable dealers and mechanics to identify replacement parts, which reduces the time for repairs to vehicles. Similar to manufacturing heavy machinery, EPCs facilitate efficient inventory management across warehouses distributed.

Through analysing cloud-based, off-premise or hybrid configurations and hybrid deployments, we can see the ways technology is able to adapt to diverse business environments ranging from small businesses looking for cost-effective solutions to larger enterprises that value the security of their data as well as internal controls.

The Right DEP Model for the EPC

Your ideal EPC deployment depends on several factors:

- Budget: Cloud offers cost savings for small businesses; on-premise works well for companies with long-term savings objectives.

- Security: In-house or hybrid systems are preferred by industries that require data.

- Access for Users: If dealers or customers require online access, a cloud or hybrid solution is more feasible.

- Integration requirements: On-premise integrates deeply with internal systems; hybrid offers an equilibrium.

- Scalability: Cloud EPC expands effortlessly with your company’s size.

The term mixed EPC is often the most balanced option that offers control as well as flexibility and scaling.

The Future EPC Deployments

The trend is shifting towards cloud-native EPC platforms that are integrated into AI-driven search, 3D visualisation and live inventory control. Manufacturers are increasingly using hybrid systems to allow for the flexibility of their systems while ensuring data security.

The new features that are emerging include:

- AI-powered Part identification with images

- Integration with IoT-enabled equipment to enable proactive maintenance

- API-based connection for online-commerce platforms

- Real-time synchronisation across global dealer networks

Final Thoughts

The decision to choose between cloud, on-premises or hybrid EPC deployments will depend on your organisation’s requirements for data policies, scalability and the IT capabilities.

- Cloud EPC provides access to the internet and cost savings.

- On-premise EPC guarantees complete control and conformity.

- Hybrid EPC offers the flexibility and performance that is balanced.

As businesses move towards digital change, adopting the correct EPC deployment method can significantly increase efficiency and operational efficiency, as well as customer satisfaction and long-term profit.

Frequently Answered Questions (FAQs)

1. What is the primary reason for the Electronic Parts Catalogue?

An EPC makes it easier to find, manage and place orders for spare parts. It provides extensive digital catalogues that are searchable and accessible to dealers, technicians or even customers.

2. Which EPC implementation is the most economical?

Cloud EPCs are the cheapest for small – to medium-sized companies due to the low upfront cost and a variety of subscription options.

3. Do I have the option of migrating out of an existing EPC on premises? EPC in the cloud?

Yes. A lot of companies slowly transition by using a mix of methods to ensure a smooth transition and little data loss.

4. Is a hybrid EPC ideal to run a global business?

Absolutely. Hybrid EPCs permit dealers from all over the world access to real-time information via the cloud while keeping confidential product data securely stored on internal servers.

5. How often do you recommend EPC information be kept up to date?

Ideally, updating should be scheduled automatically or on a regular basis to ensure accuracy in prices, part numbers, and availability.