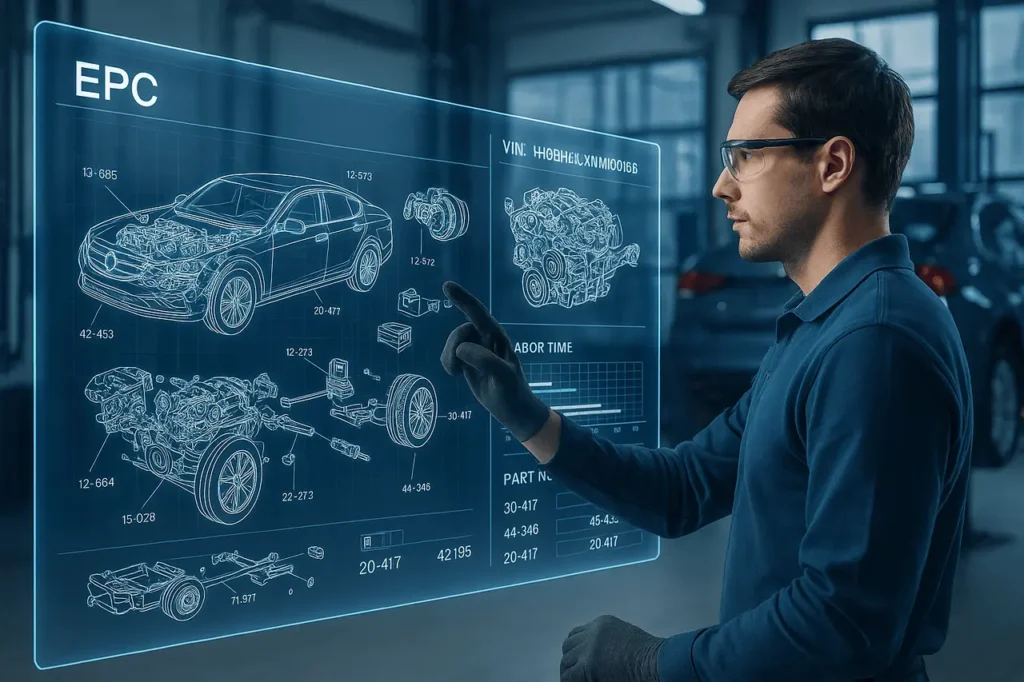

The accuracy of repair and labour time estimation is vital for every auto workshop dealer, part distributor or independent mechanic. Customers demand transparency, businesses require speed, and mechanics require reliable information to plan their tasks. The most effective instrument for accomplishing these goals is Electronic Parts Catalogue (EPC).

Modern EPC systems do more than list spare parts. They include diagrams, technical service information, labour time guidelines, and model-specific compatibility information, which aid in estimating labour hours, repair time frames, and overall job costs.

This article explains how using EPC to estimate Labour and Repair Time improves estimation accuracy and how businesses can utilise it to streamline operations and boost productivity.

What is an Electronic Parts Catalog (EPC)?

An electronic Parts Catalogue (EPC) is a catalogue in digital format which provides:

- Complete lists of parts for machinery or vehicles

- Diagrams that explode and layouts of components

- Part numbers, compatibility information and the history of supersessions

- Repair instructions and procedures for service

- Time estimates for labour for specific jobs

- VIN-based tools for identification and lookup

Nearly every major OEM and parts distributor utilises EPC systems, ranging from automobile brands such as Toyota, BMW, and Ford to heavy-equipment producers and aftermarket distributors.

In contrast to traditional PDF manuals, EPCs offer a fast search feature with real-time updates, as well as interactive diagrams, which help reduce errors in repair estimation and planning.

Why EPC Is Essential for Estimating Labour & Repair Time

1. Access to Manufacturer-Backed Labour Time Standards

OEM EPCs typically contain recommended labour time estimates for specific repair tasks, for example:

- Replacing brake pads

- Swapping timing belts

- Repairing suspension components

- Perform the disassembly of the engine or transmission

The standardised times are determined through controlled tests conducted by the manufacturer. Thus, technicians are provided with a stable base that prevents overcharging and underestimating.

2. Accurate Identification of Required Parts

Incorrect selection of the part can delay work and add hours to the labour time. EPC systems remove the guesswork by displaying:

- This is the exact number of parts

- Parts that are superseded or upgraded

- Specific versions of the engine or trims

- Quantity needed

- All the necessary components to complete the task

Because incorrect or missing parts frequently result in longer work durations, EPC records keep repair timing precise and predictable.

3. Exploded Diagrams Improve Time Estimation

Interactive diagrams show the connections between components, the number of bolts involved, what needs to be removed beforehand, and whether hidden parts could hinder the process.

This assists technicians in estimating:

- The time to disassemble the unit

- Time for component removal

- The time is now for reassembly

- Other tasks that are not immediately apparent

This helps avoid surprises during the work.

4. VIN-Based Lookup Ensures Model-Specific Accuracy

The same vehicle model may have distinct components depending on the region, year, engine, or manufacturing batch. The use of the VIN in EPC assures an exact identification of

- Component layout

- Types of fasteners

- Electrical connections

- Repair complexity

The estimates of labour are based on the exact car, but not general figures.

5. Service Bulletins and Procedure Notes

Many EPCs include Service Bulletins (TSBs) which specify:

- New repair procedures for repairs

- Additional steps are required

- Special tool instruction

- New recommendations on labour time

These bulletins can significantly alter the duration of labour, and EPC ensures you are aware of the latest information.

How to Use EPC to Estimate Labour & Repair Time (Step-By-Step)

Step 1: Identify the Vehicle Using VIN

Before you begin any repair estimate, it is vital to determine the car’s model using its VIN. This will help filter out parts, variations and procedures that do not apply to the particular model. Using the VIN ensures that all labour time and parts information is 100% accurate for the specific model being repaired.

Key Points:

- Removes obsolete or incorrect components

- This prevents inaccurate estimates of labour due to model differences

- It ensures that parts are compatible with each other and that repair procedures are

Step 2: Search for the Component or System

After the vehicle has been identified, the next step is to determine which component or system needs repair. EPC platforms organise components into distinct categories, making it easier to find the component you require. A well-organised search will ensure the correctness of each element in the repair estimate process.

Common Categories to Navigate:

- Engine

- Transmission

- Suspension

- HVAC

- Electrical

- Body components

Step 3: Review Exploded Diagrams

Diagrams with explosions offer an overview of each component and its connections. The diagrams aid technicians in understanding which parts must be removed first to access the sections and the overall removal sequence. The diagram is thoroughly reviewed to ensure the most accurate estimate of the repair duration and potential problems.

What to Look For:

- Components that require removal

- The accessibility of fasteners, as well as hidden parts

- Step-by-step disassembly flow

- The potential for complications or additional work required

Step 4: Access Labour Time Data

OEM EPC systems usually include detailed labour time sections that describe the time required to completed each repair under normal conditions. The times are analysed by the company that produces them and serve as reliable guidelines for technicians. This data is the foundation of your labour estimation.

Common EPC Labour Time Labels:

- Standard Labour Time

- Flat Rate Time

- Repair Time Estimate

- Technician Work Time

Step 5: Add Additional Time for Condition-Based Factors

Although EPC provides a precise base, actual vehicles rarely meet ideal test conditions. Older vehicles, corrosion-prone bolts, altered components, or a lack of access could dramatically increase repair time. By adding a reasonable buffer time, the final estimate is based on actual working conditions in the workshop.

Factors That Increase Labour Time:

- Bolts that are rusted or seized

- Wear or damaged components

- Access to areas that are restricted or tight

- Modifications to the aftermarket

- More time is used to perform the process of diagnosing

Step 6: Combine Parts and Labour for Final Estimate

The final step involves combining the EPC labour time with the required parts to complete the task. EPC offers precise parts numbers, quantities, and compatibility information, making cost calculation simple when you add these numbers to the adjusted hours of labour to give you the most complete and precise repair estimate.

What to Include in the Final Estimate:

- The total cost of the components

- Standard hours of work

- Additional work-related labour

- Other material or consumables

Benefits of Using EPC to Estimate Labour and Repair Time

Improved Accuracy

Using EPC ensures that estimates are based on manufacturer-approved data rather than guesswork. The accuracy of the information decreases the risk of underestimating or overcharging. This results in more consistent and efficient repair planning.

Advantages:

- Specific labour and parts information

- Fewer estimation errors

- Pricing that is consistent and reliable

Faster Turnaround

Technicians can save time by locating all data in a single central EPC system. It is no longer necessary to manually browse through a variety of manuals or outdated sources—quicker preparation results in more efficient repairs.

Benefits:

- Quick lookup of a part

- Information on the labour time of an instant

- Smoother workflow

Better Customer Trust

Accurate and transparent estimates will help you build solid relationships with clients. When customers see a precise, reliable estimate, they feel more confident about approving repairs. This can lead to long-term customer retention and increased customer satisfaction.

Trust-building Factors:

- A clear breakdown of costs

- Reliable repair timelines

- Professional presentation

Reduced Returns and Rework

Making sure the right parts are used and following the correct procedures reduces the risk of failures during repair. EPC helps technicians avoid errors in diagnosis or improper installation of parts. This increases efficiency in workshops and reduces operating losses.

Impact:

- Fewer errors

- Rework time is shorter

- Quality and overall higher

Increased Workshop Profitability

An accurate estimation of labour guarantees that workers aren’t underpaid or overworked. This can help improve the scheduling process and distribution of labour. Better planning leads to better profitability and more efficient operations.

Profit Boosters:

- Utilising the time of technicians efficiently

- A proper job assignment

- Management of balance in workload

Common Mistakes When Using EPC for Labour Estimation

Relying Only on OEM Times

OEM times are based on ideal conditions for workshop work, but these seldom correspond to real-world situations. Technicians must be aware of the vehicle’s actual condition. Inadequate adherence to OEM timeframes can result in inaccurate estimates.

Risks:

- Overestimating the length of work

- Unhappy customers

- Technician overload

Using an Outdated EPC Version

An old EPC may include old part numbers or inaccurate labour time information. Be sure your system is up to date to the latest version. This will prevent errors that could delay repairs or result in incorrect parts orders.

Consequences:

- Incorrect part identification

- Part numbers that are obsolete or superseded

- Misleading repair instructions

Not Verifying VIN Information

The omission of VIN validation could lead to selecting the wrong version or market for parts. A minor thing, like a slight difference in the trim level, can drastically alter the repair process. Always verify the VIN before proceeding.

Issues It Causes:

- The wrong part was selected

- Incorrectly calculated labour time

- Repair delays

Misinterpreting Diagrams

Diagrams with explosions need to be carefully inspected to avoid misinterpretation. Incorrect interpretation could lead to errors or insufficient assembly planning. A thorough understanding of the diagram is essential to ensure smooth operation.

Potential Problems:

- Missing essential parts

- Underestimating complexity

- Repair errors

Overlooking Subcomponents

Most repair tasks require more clips, fasteners, brackets or seals, which technicians could overlook. Incorrectly identifying these components can unexpectedly increase the time to complete the work. Always look for the associated sub-components within the EPC.

Why It Matters:

- Gives exact parts lists

- Complete repair planning

- Prevents last-minute delays

Final Thoughts

Utilising an electronic Parts Catalogue (EPC) to calculate labour and repair time is among the most efficient ways for auto shops and workshops to increase accuracy, improve efficiency, and offer affordable prices to their customers. With clear diagrams, current information on parts and OEM standards for labour, EPC transforms guesswork into accurate scheduling. When combined with technicians’ expertise and real-world conditions, EPC becomes a powerful tool for faster repairs, higher productivity, and greater customer satisfaction.

FAQs About Using EPC to Estimate Labour and Repair Time

1. Does EPC always include labour time estimates?

The majority of OEM EPCs include labour times; however, some aftermarket EPCs provide only information on the parts. For complete repair details, you need to combine the EPC with a workshop manual.

2. Can EPC labour time be used to bill customers?

Yes. OEM labour time is an industry-standard reference for job pricing and customer estimates.

3. Does EPC take over diagnostic tools?

No. EPC aids the planning process, and identifying parts and diagnostic tools helps find the source of problems.

4. Are EPC time-to-work estimates accurate for older cars?

The time to labour is precise for baseline conditions. Older vehicles may require adjustments due to rust, wear, or prior repairs.

5. Does EPC assist in the training of technicians?

Absolutely. EPC diagrams and instructions help students understand the structure of components and the repair process.

6. Is EPC helpful for modified or aftermarket vehicle models?

EPC is the best choice for OEM configurations. Modified vehicles might require special assessments.